Audi Q3: Refrigerant Oil

General Information

Caution

Caution

When handling refrigerant oil, pay attention to local regulations.

Refrigerant oil mixes with the refrigerant (about 20-40%, depending on compressor type and amount of refrigerant) and circulates constantly in the system, lubricating the moving parts.

Special synthetic refrigerant oils, for example polyalkylene glycol (PAG) oil, are used in conjunction with R134a air conditioning systems. This is necessary as mineral oil, for example, does not mix with R134a. In addition, the materials of the R134a air conditioning system could be corroded as a result of mixture flowing through the refrigerant circuit under pressure at high temperatures or breakdown of the lubricating film in the compressor. Using non-approved oils can cause the HVAC system to malfunction. Only use approved oils.

Refer to the Parts Catalog.

Type of oil for R134a in motor vehicles: PAG. (Polyalkyleneglycol)

Note

Note

- Do not store open containers of refrigerant oil because it attracts moisture.

- Always keep oil containers sealed.

- Do not use old refrigerant oil over again. For disposing refrigerant oil of unknown origin pay attention to local regulations.

- Ester-based oils are only intended for use in large systems at this time, not in passenger vehicle systems.

Refrigerant Oil Characteristics

The most important properties are a high degree of solubility with refrigerant, good lubricity, absence of acid and minimal water content. Only certain oils are permitted. For a list of approved refrigerant oils and capacities. Refer to → Chapter "Approved Refrigerant Oils and Capacities".

PAG oils, which are appropriate for refrigerant R134a, are highly hygroscopic and do not mix with other oils. Opened containers should therefore be closed again immediately to prevent ingress of moisture. Moisture and acids promote aging of refrigerant oil, causing it to become dark and viscous as well as corrosive towards metals.

Note

Note

- Refrigerant oil, because of its chemical properties, must not be disposed of with engine oils or transmission oils. For disposing refrigerant oil of unknown origin pay attention to local regulations.

- Only the oil approved for the A/C compressor may be used in refrigerant circuits with refrigerant R134a. For the correct oil. Refer to the Parts Catalog. For the correct capacities. Refer to → Chapter "Approved Refrigerant Oils and Capacities".

A/C System Operation

General Information

The temperature in the passenger compartment depends on the amount of heat radiated through the windows and conducted by the metal parts of the body. In hot weather it is possible to achieve a more comfortable temperature for the passengers by pumping off some of the heat.

As heat spreads into cooler areas, the passenger compartment is equipped with a unit for generating low temperatures. In the unit, refrigerant is constantly evaporated. The heat required for this is extracted from the air flowing through the evaporator.

After absorbing heat, the refrigerant is pumped off through the compressor. The action of the A/C compressor increases the heat content and temperature of the refrigerant. Its temperature is then substantially higher than that of the surrounding air.

The warm refrigerant flows to the condenser. There, the refrigerant dissipates its heat through the condenser to the surrounding air due to the temperature difference between the refrigerant and air.

The refrigerant thus acts as a heat transfer medium. As it is to be reused, the refrigerant is returned to the evaporator.

For this reason all air conditioning systems are based on the refrigerant circulation principle. There are however differences in the combination of aggregates.

Comfort

Being comfortable while driving leads to better concentration and safe driving. Air conditioning makes drivers and passengers more comfortable when temperatures or humidity are high. While opening the windows or sunroof or increasing the air flow can make vehicle occupants more comfortable, it also exposes them to more noise, draughts, exhaust, pollen and dust.

A well-designed heating and air conditioning system can increase comfort by controlling the temperature, humidity and air flow inside the vehicle. This is done both when the vehicle is moving and when it is stationary.

Air conditioning also offers these advantages:

- It cleans the air that enters the vehicle interior. The damp fins on the evaporator collect dust and pollen, which is then removed by condensation.

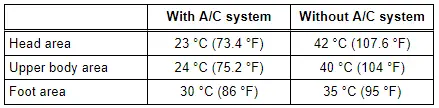

- Temperatures in a mid-size vehicle (for example: after a short drive, outside temperature 30 ºC (86 ºF) in the shade and the vehicle exposed to sunlight).

Environmental Information

Since roughly 1992, the air conditioning systems of newly manufactured cars have been successively converted to refrigerant R134a. This refrigerant does not contain chlorine and does not deplete the ozone layer.

Until roughly 1992, refrigerant R12 was used for air conditioning systems. Due to its chlorine atoms, this CFC has a high potential for depleting the ozone layer as well as a tendency to increase the greenhouse effect.

Conversion programs are available for old existing systems filled with the ozone-depleting substance R12. Refer to Repair Manual for A/C Systems with Refrigerant R12 (this repair manual is only available in hard copy).

The greenhouse potential of R134a (Global Warming Potential = GWP) is approximately 1400, for this reason the European commission has committed that from 01/01/2017 no vehicles with this can newly be brought into the market. Refer to → Chapter "Refrigerant R134a Environmental Information". For this reason from 2016 for new vehicles a refrigerant with a GWP smaller than 150 in introduced (for example the refrigerant R1234yf with a GWP less than 5).

For environmental protection reasons, refrigerants must not be released into the atmosphere. For laws and regulations. Refer to → Chapter "Laws and Regulations".

General Safety Precautions

- As per VBG 20, German industrial liability insurance association.

- Pay attention to the workshop-specific instructions. It should be kept in the workshop.

Product Characteristics

Refrigerants used in motor vehicle air conditioning systems belong to the new generation of refrigerants based on chlorine-free, partially fluorinated hydrocarbons (H-FKW, R134a).

With regard to their physical properties, these are refrigerants which have been liquefied under pressure. They are subject to the regulations governing pressure containers and use is only to be made of approved and appropriately marked containers.

Compliance with specific conditions is required to ensure safe and proper use.

Handling Refrigerant

If refrigerant containers are opened, the contents may escape in liquid or vapor form. This process is intensified the higher the pressure in the container.

The pressure level is governed by two factors:

- The type of refrigerant in the container. "The lower the boiling point, the higher the pressure."

- The temperature level. "The higher the temperature, the higher the pressure."

WARNING

WARNING

- There is a danger of ice-up.

- The refrigerant can then escape as a fluid or vapor.

- Do not open containers which store refrigerant.

Protective Eyewear

Put on protective goggles. They prevent refrigerant getting into the eyes, as this could cause severe injury from exposure to cold.

Protective Gloves and Clothing

Greases and oils dissolve readily in refrigerants. They would therefore destroy the protective layer of grease if allowed to come into contact with the skin. Degreased skin is however sensitive to the cold and germs.

Fluid Refrigerant and Skin Precaution

The refrigerant draws heat for evaporation from the surrounding area. Even if this is the skin. This may cause extremely low temperatures. Local frost bite may result (boiling point of R134a: -26.5 ºC (-15.7 ºF) at ambient pressure).

Refrigerant Vapor Precaution

If highly concentrated refrigerant vapor escapes, it mixes with the surrounding air and displaces the oxygen necessary for breathing.

Welding and Soldering on Refrigeration Systems

Before performing welding or soldering work on vehicles near A/C system components, extract the refrigerant and remove remnants by blowing them out with nitrogen.

The products of refrigerant decomposition due to the effect of heat are not only toxic, but may also have a highly corrosive effect on pipes and system components. They mainly take the form of hydrogen fluoride.

Pungent Odor

A pungent odor indicates that the products of decomposition mentioned above have already formed. Avoid inhaling these substances under all circumstances, as otherwise the respiratory system, lungs and other organs could be damaged.

First Aid

- Following contact with eyes or mucous membranes, immediately rinse with copious amounts of running water and consult an eye specialist.

- Following contact with the skin, immediately remove affected clothing and rinse skin with copious amounts of water.

- Following inhalation of highly concentrated refrigerant vapors, immediately take the affected person into the open air. Call a doctor. Administer oxygen in the event of breathing difficulties. If the affected person has difficulty breathing or cannot breathe, tip head back and perform mouth to mouth respiration.

Also refer to → Chapter "Handling Pressure Containers".

Handling Pressure Containers

Secure containers to prevent them falling over!

Secure upright cylinders to stop them falling over and cylinders lying flat to stop them rolling away.

Do not throw containers!

If dropped, the containers could be so severely deformed that they rupture. The refrigerant evaporates immediately, liberating considerable force. Flying fragments of cylinders can cause severe injuries.

To protect the valves, cylinders are only to be transported with protective cap screwed on.

Valves may break off if cylinders are not properly transported.

Never store in the vicinity of radiators.

High temperatures may occur next to radiators. High temperatures are also accompanied by high pressures and the maximum permissible container pressure may be exceeded.

Not Warming Above 50 ºC (122 ºF)

To avoid possible risk, pressure container regulations specify that containers are not to be heated to in excess of 50 ºC (122 ºF).

Heating Warning

Do not heat with a naked flame under any circumstances. Localized overheating can cause structural changes in the container material, which then reduce its ability to withstand pressure. There is also a danger of refrigerant decomposition due to localized overheating.

Empty Containers

Empty refrigerant containers must always be sealed to prevent the ingress of moisture. Moisture causes steel containers to corrode. This weakens the containers walls. In addition, rust particles entering into refrigeration systems from containers will cause malfunctioning.

Extraction and Charging System Safety Regulations

- Make sure the shut-off valves are closed before connecting the charging system to the air conditioning system.

- Before disconnecting the charging system from the air conditioning system, make sure the charging process has been completed to stop refrigerant escaping into the atmosphere.

- Once the purified refrigerant from the charging system has been transferred to an external compressed-gas cylinder, close the hand shut-off valves at the cylinder and charging system.

- Do not expose charging system to moisture or use it in a wet environment.

- Disconnect from power supply before performing service work on the charging system.

- Never use an extension cable on account of the fire hazard. If the use of an extension cable is unavoidable, the minimum cross-section should be 2.5 mm2.

- In case of fire, remove the external cylinder.

- Entrained oil from the air conditioning system drawn by the suction unit into the measurement container supplied is subsequently to be transferred to a sealed container as it contains a small quantity of refrigerant. It must not be released into the environment.

- Following shutdown, the service station is to be secured to stop it rolling away.