Audi Q3: Trailing Arm, Servicing

Trailing Arm, Servicing, FWD Vehicles

Special tools and workshop equipment required

- Press Plate -VW401-

- Press Plate -VW402-

- Front Subframe Mount Kit -3372-

- Hydraulic Press - Bushing Assembly Tool Kit -T10230-

Pressing out the bonded rubber bushing

- Remove trailing arm with mounting bracket. Refer to → Chapter "Trailing Arm with Mounting Bracket, Removing and Installing, FWD Vehicles".

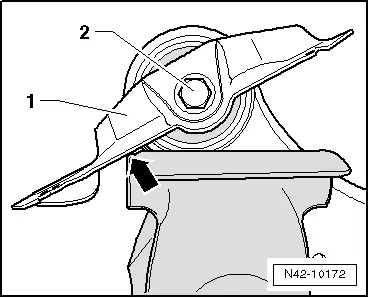

- Clamp the trailing arm in the vise so that the mounting bracket -1- contacts the vise -arrow-.

- Remove the bolt -2-.

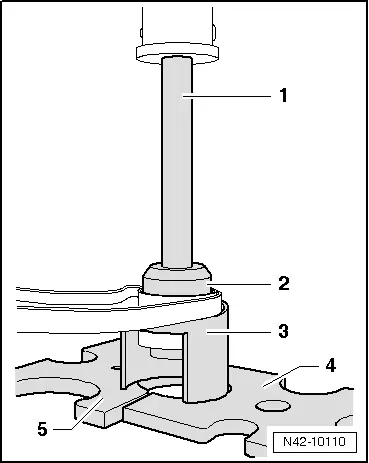

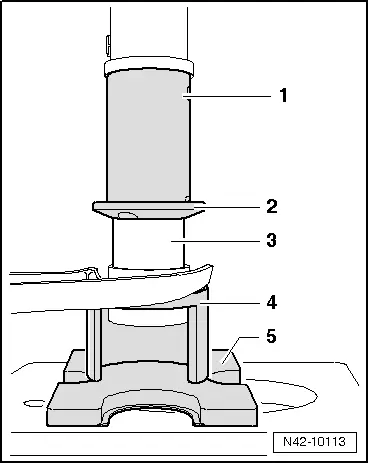

- Install tools as shown in the illustration.

1 - Hydraulic Press - Bushing Assembly Tool Kit-Pipe -T10230/3-

2 - Hydraulic Press - Bushing Assembly Tool Kit-Press Piece -T10230/10-

3 - Front Subframe Mount Kit -3372-

4 - Press Plate -VW401-

5 - Press Plate -VW402-

- Press out the bonded rubber mount.

Installing the bonded rubber bushing

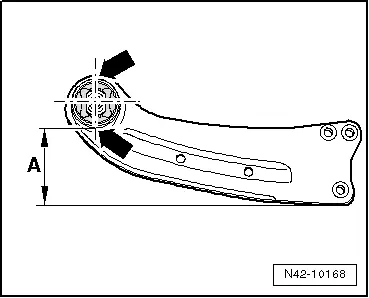

- Place the trailing arm on a flat surface.

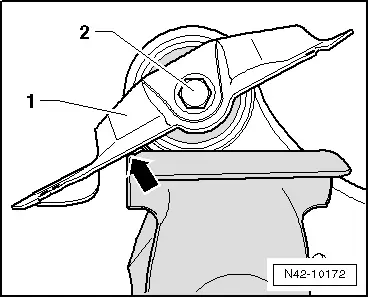

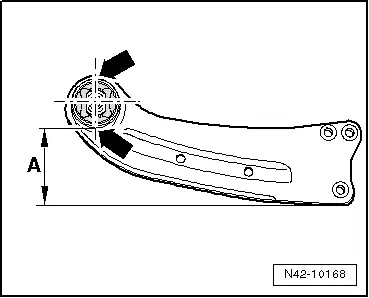

- Position the trailing arm so that the dimension -A- 113 mm is reached.

- In this position, apply a vertical line (marking on the upper and lower edge of the bushing) that is centered with the trailing arm bushing -arrows-.

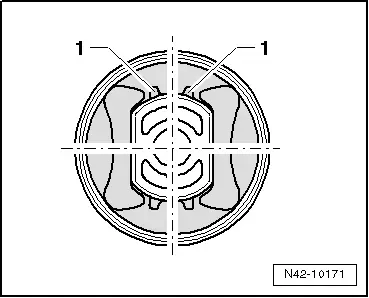

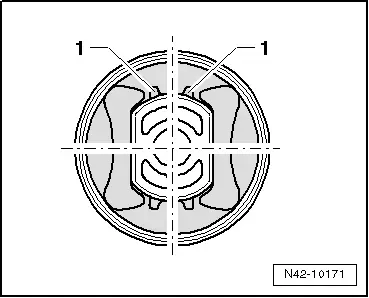

- Position the bonded rubber bushing on the trailing arm so that the marked line is between the raised sections -1-.

Note

Note

Always make sure that the bonded rubber bushing is in the correct installation position to the trailing arm bushing.

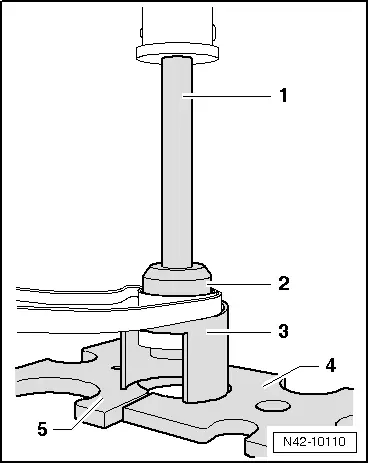

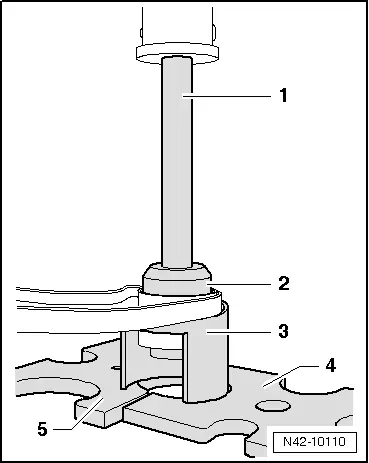

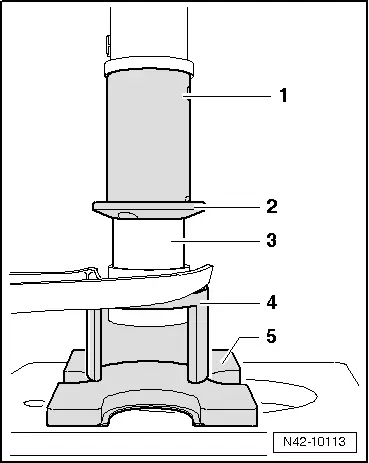

- Install tools as shown in the illustration.

1 - Hydraulic Press - Bushing Assembly Tool Kit - Tube -T10230/5-

2 - Hydraulic Press - Bushing Assembly Tool Kit-Thrust Plate -T10230/12-, the chamfer must face the bonded rubber bushing

3 - Bonded rubber bushing

4 - Front Subframe Mount Kit -3372-

5 - Press Plate -VW402-

- Press in bonded rubber bushing flush.

- Install the mounting bracket on trailing arm.

- Install trailing arm with mounting bracket. Refer to → Chapter "Trailing Arm with Mounting Bracket, Removing and Installing, FWD Vehicles".

Trailing Arm, Servicing, AWD Vehicles

Special tools and workshop equipment required

- Press Plate -VW401-

- Press Plate -VW402-

- Front Subframe Mount Kit -3372-

- Hydraulic Press - Bushing Assembly Tool Kit -T10230-

Pressing out the bonded rubber bushing

- Remove trailing arm with mounting bracket. Refer to → Chapter "Trailing Arm with Mounting Bracket, Removing and Installing, FWD Vehicles".

- Clamp the trailing arm into vise so that the mounting bracket -1- makes contact at vise -arrow-.

- Remove the bolt -2-.

- Install tools as shown in the illustration.

1 - Hydraulic Press - Bushing Assembly Tool Kit-Pipe -T10230/3-

2 - Hydraulic Press - Bushing Assembly Tool Kit-Press Piece -T10230/10-

3 - Front Subframe Mount Kit -3372-

4 - Press Plate -VW401-

5 - Press Plate -VW402-

- Press out the bonded rubber mount.

Installing the bonded rubber bushing

- Place the trailing arm on a flat surface.

- Position the trailing arm so that the dimension -A- 113 mm is reached.

- In this position, apply a vertical line (marking on the upper and lower edge of the bushing) that is centered with the trailing arm bushing -arrows-.

- Position the bonded rubber bushing on the trailing arm so that the marked line is between the raised sections -1-.

Note

Note

Always make sure that the bonded rubber bushing is in the correct installation position to the trailing arm bushing.

- Install tools as shown in the illustration.

1 - Hydraulic Press - Bushing Assembly Tool Kit - Tube -T10230/5-

2 - Hydraulic Press - Bushing Assembly Tool Kit-Thrust Plate -T10230/12-, the chamfer must face the bonded rubber bushing

3 - Bonded rubber bushing

4 - Front Subframe Mount Kit -3372-

5 - Press Plate -VW402-

- Press bonded rubber bushing in flush.

- Install the mounting bracket on trailing arm.

- Install trailing arm with mounting bracket. Refer to → Chapter "Trailing Arm with Mounting Bracket, Removing and Installing, FWD Vehicles".