Audi Q3: Chip Card Reader Control Module, Removing and Installing

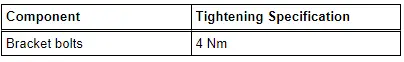

The Chip Card Reader Control Module -J676--1- is located inside the glove compartment -2-.

Removing

- Turn off the ignition and all electrical equipment and remove the ignition key.

- Remove the glove compartment. Refer to → Body Interior; Rep. Gr.68; Storage Compartment/Covers; Glove Compartment, Removing and Installing.

- Release and disconnect the connectors from the Chip Card Reader Control Module -J676-.

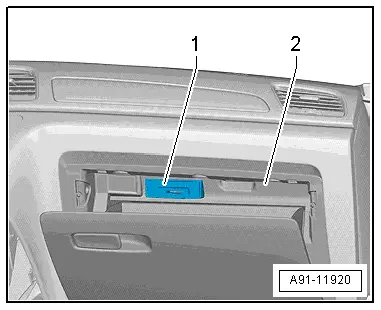

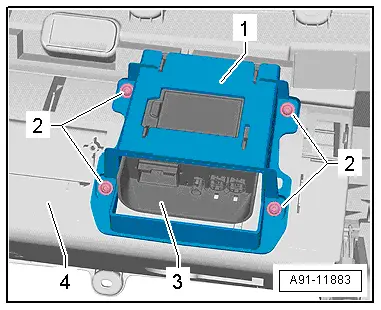

- Remove the bolts -2- from the bracket -1-.

- Remove the bracket -1- with Chip Card Reader Control Module -J676--3- from the glove compartment -4-.

- Remove the Chip Card Reader Control Module -J676- from the bracket.

Installing

- Install in reverse order of removal. Note the following:

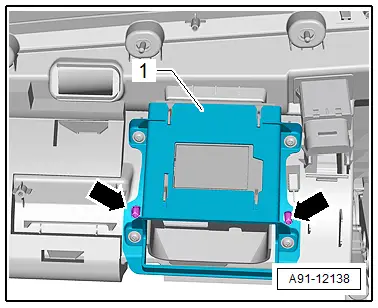

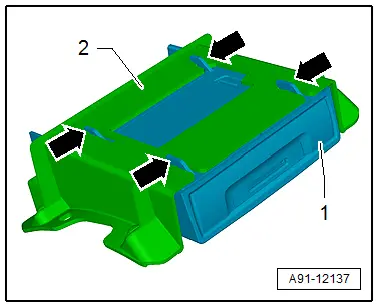

- Push the Chip Card Reader Control Module -J676--1- in the bracket -2- until it engages "audibly"-arrows-.

- Pay attention when installing the bracket -1- that the dome -arrows- on the bracket -1- are seated correctly.