Audi Q3: Connector Housings and Connectors, Repairing

Connector Housings and Connectors, Repair Information

Note

Note

- Observe general notes for repairs on the vehicle electrical system. Refer to → Chapter "Vehicle Electrical System, General Repair Information".

- Allocation of crimp contacts with correct fit to connector housing is performed according to the part number stamped in on the connector housing. Refer to the Parts Catalog; Special Catalog "Electrical Connecting Components"; Electrical Equipment; subgroup 71 chart 970-00.

- Damaged connector housings must always be replaced.

Contacts in Connector Housing, Repairing

Procedure

- First, open or release if necessary the secondary lock of the connector housing. Refer to → Chapter "Connector Housings, Releasing and Disassembling".

- Release contact (primary lock) using the appropriate release tool. Refer to → Chapter "Connector Housings, Releasing and Disassembling".

- Pull the contact back out of the connector housing -arrow- at the single wire (with the single wire seal if necessary).

- Cut off the old contact (with the single wire seal) from the vehicle-specific wiring harness.

- Take the yellow repair wire with the correct contact out of the Wiring Harness Repair Set -VAS1978B-.

- Free up the wire to be repaired approximately 20 cm on both sides of the repair point.

Caution

Caution

Risk of damaging the electrical wires.

Expose wrapped wiring harnesses carefully.

- If necessary, removing the wiring harness wrapping using a knife.

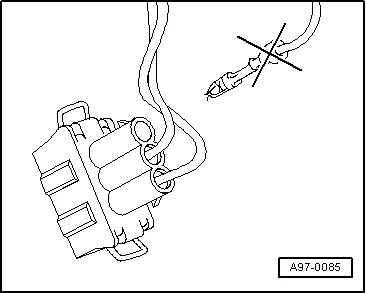

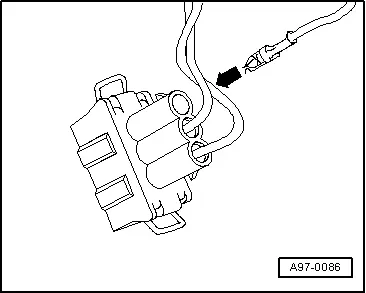

- Slide the new repair wire contact into the corresponding connector housing compartment until it engages.

- If necessary, install the single wire seal on the repair wire. Refer to → Chapter "Single Wire Seals, Installing".

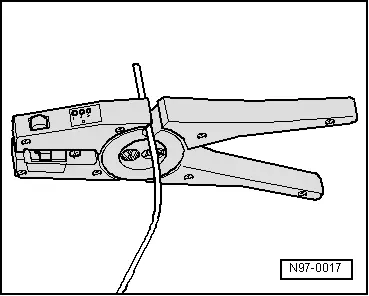

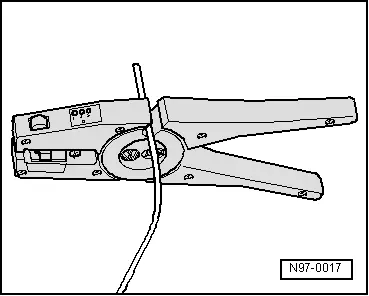

- Shorten the repair wire and the vehicle-specific wiring harness single wire as needed using the Wiring Harness Repair Set - Wire Strippers -VAS1978/3-.

- Remove the insulation from the ends of the repair wire and vehicle-specific single wire and crimp the ends with the crimping wires and a crimp connector. Refer to → Chapter "0.22 mm 2 Wire, Repairing with Individual Crimp Connector" or → Chapter "Repairing a Wire 0.35 mm 2 or Greater with Individual Crimp Connector".

Single Wire Seals, Installing

Procedure

Note

Note

- Single wire seals prevent the penetration of water and dirt into the connector housing. They are installed, for example, in the engine compartment and must be reinstalled after a repair.

- Single wire seal is crimped on at the factory together with contact on the wire, this is not the case for repair wires. The single wire seal must be slid onto the wire before crimping the repair wire.

- Single wire seals must always fit with the repair wire cross-section. Outer circumference of single wire seal is aligned according to chamber circumference of the connector housing. Perform assembly using only the assembly tool with correct fit.

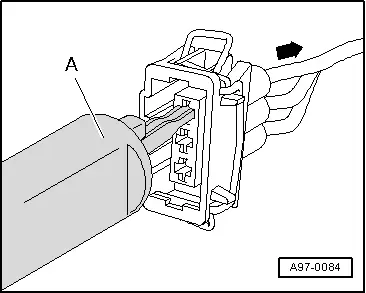

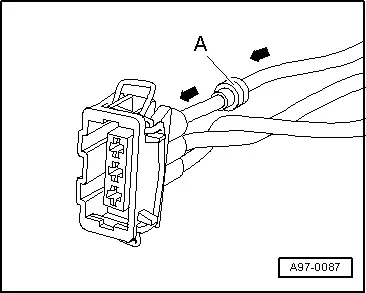

- Put single wire seal -A- onto free end of repair wire.

- When doing this, the single wire seal small diameter must point toward the connector housing.

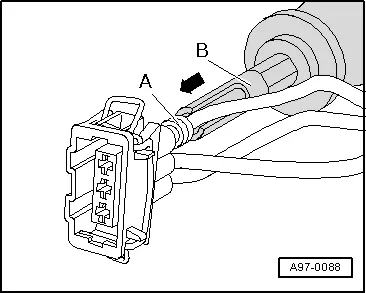

- Slide the single wire seal -A- onto the repair wire up to the connector housing and then into the housing as far as the stop using the appropriate assembly tool -B-.

- Shorten the repair wire and the vehicle-specific wiring harness single wire as needed using the Wiring Harness Repair Set - Wire Strippers -VAS1978/3-.

- Crimp the stripped ends of repair wire and single wire of vehicle-specific wiring harness using crimping pliers and a crimping pliers. Refer to → Chapter "0.22 mm 2 Wire, Repairing with Individual Crimp Connector" or → Chapter "Repairing a Wire 0.35 mm 2 or Greater with Individual Crimp Connector".

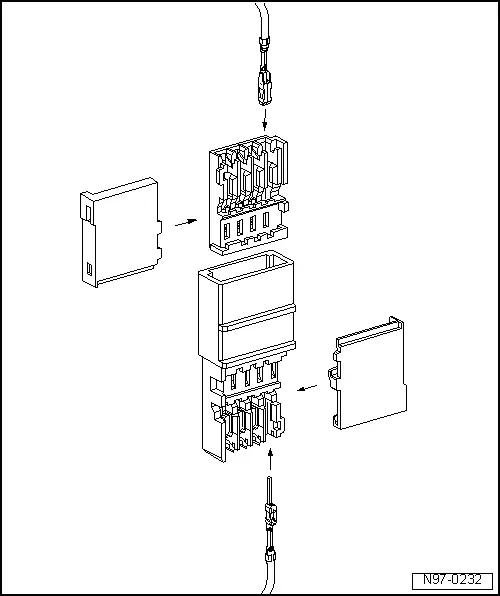

Connector Housing with Insulation Displacement Connections, Repairing

Note

Note

- For technical reasons, the connector housing for the wire terminals can be supplied only with the contacts pushed in.

- These contacts can be removed at every other connector housing in the event they are not required.

- Repair wires which have already been equipped with corresponding contacts crimped on are available. Refer to the Parts Catalog.