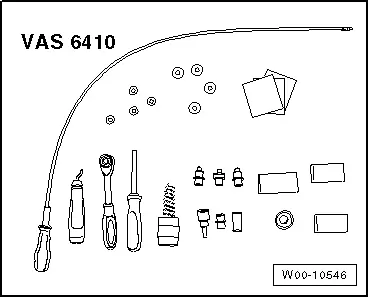

Audi Q3: Contact Surface Cleaning Set -VAS6410-

Contact Surface Cleaning Set -VAS6410-, Using

The Contact Surface Cleaning Set -VAS6410- makes optimal repair quality possible in the realm of vehicle electronics. Using the tools, service work can be performed in the area of the contact sensor on the threaded connection wiring harnesses in the high current circuit (starter and charging current). The Contact Surface Cleaning Set -VAS6410- is adapted to the vehicle structural measurements and ensures correct servicing and a comfortable procedure.

Note

Note

The illustrations of the service work only serve as examples.

Contact Surface Cleaning Set -VAS6410-

Wiring Eyelets, Repairing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

Note

Note

- Do not use rust remover, contact spray or grease because the lack of friction will cause the torque to be exceeded when installing and this will lead to the threaded connection breaking.

- The gray sanding pads are for slight contamination and suitable for "soft surfaces". The red sanding pads are for heavy contamination and suitable for "hard surfaces".

WARNING

WARNING

Risk of injury. Observe warning notes and safety precautions. Refer to → Chapter "Warnings and Safety Precautions".

- Disconnect battery.

- Loosen the cap nut and remove the wiring eyelet from the threaded connection.

- Check the wiring eyelet for corrosion, contamination, etc.

- Select the corresponding adapter and the corresponding sanding pad.

Note

Note

The sanding block can be used instead.

Caution

Caution

Make sure the tin layer is not worn down too much and the copper is not visible. A galvanic element can form from this, destroying the metal and causing incorrect repairs.

Note

Note

Due to the different thicknesses of the tin layer, the cleaning process must be performed in several steps and a visual inspection of the wiring eyelet between steps is necessary.

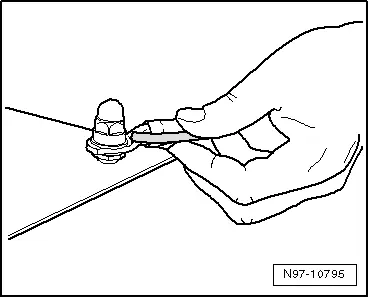

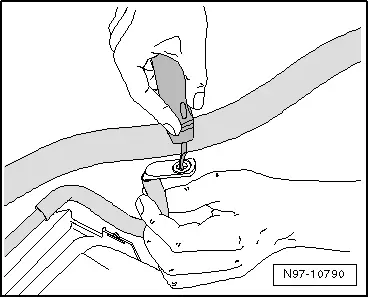

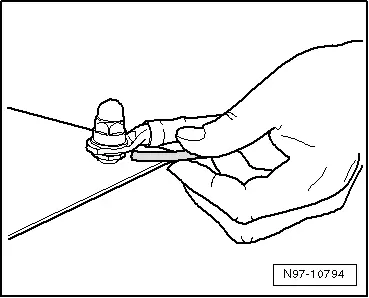

- Insert the adapter in the wiring eyelet and sand off the corrosion and contamination with circular motions.

- Check the wiring eyelet and sand it again if necessary.

- If necessary, remove the burr on the wiring eyelet with the deburrer.

- Reinstall the wiring eyelet with the specified torque. Refer to → Wiring diagrams, Troubleshooting & Component locations

Note

Note

Optimal contact is ensured if the bolted components are tightened to the specified torque after cleaning.

- Apply protection material to the connection. Refer to → Chapter "Protecting".

- Reconnect the battery.

WARNING

WARNING

Risk of injury. Prior to handling or servicing batteries, read, understand and observe the Warning and Safety Measures. Refer to → Chapter "Warnings and Safety Precautions"

- Reprogram the window regulators, enter the radio code, set the clock and, if necessary, recode the control modules that have error messages.

Threaded Connections, Repairing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

Note

Note

- Do not use rust remover, contact spray or grease because the lack of friction will cause the torque to be exceeded when installing and this will lead to the threaded connection breaking.

- The gray sanding pads are for slight contamination and suitable for "soft surfaces". The red sanding pads are for heavy contamination and suitable for "hard surfaces".

WARNING

WARNING

Risk of injury. Prior to handling or servicing batteries, read, understand and observe the Warning and Safety Measures. Refer to → Chapter "Warnings and Safety Precautions"

- Disconnect battery.

- Loosen the cap nut and remove the wiring eyelet from the threaded connection.

- Check the threaded connection for corrosion, contamination, etc.

- Select the corresponding adapter and the corresponding sanding pad for the threaded connection.

Caution

Caution

Make sure the tin layer is not worn down too much and the copper is not visible. A galvanic element can form from this, destroying the metal and causing incorrect repairs.

Note

Note

Due to the different thicknesses of the tin layer, the cleaning process must be performed in several steps and a visual inspection of the wiring eyelet between steps is necessary.

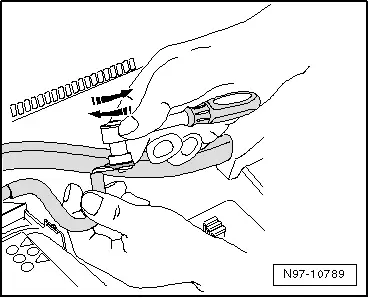

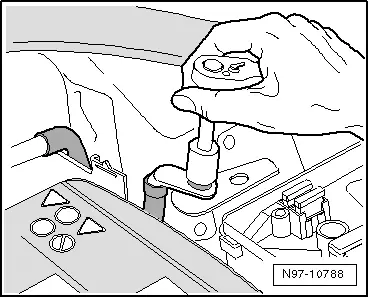

- Place the adapter on the threaded connection and sand off the corrosion and contaminants with circular movements.

- Check the threaded connection and sand it again if necessary.

- Retighten the connection and, if necessary, the anti-rotation protection to the specified torque. Refer to → Wiring diagrams, Troubleshooting & Component locations.

Note

Note

Optimal contact is ensured if the bolted components are tightened to the specified torque after cleaning.

- Apply protection material to the threaded connection. Refer to → Chapter "Protecting".

- Reconnect the battery.

WARNING

WARNING

Risk of injury. Prior to handling or servicing batteries, read, understand and observe the Warning and Safety Measures. Refer to → Chapter "Warnings and Safety Precautions"

- Reprogram the window regulators, enter the radio code, set the clock and, if necessary, recode control modules that have error messages.

Battery Terminal Clamp and Battery Terminal, Cleaning

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

Note

Note

Do not use rust remover, contact spray or grease because the lack of friction will cause the torque to be exceeded when installing and this will lead to the threaded connection breaking.

WARNING

WARNING

Risk of injury. Prior to handling or servicing batteries, read, understand and observe the Warning and Safety Measures. Refer to → Chapter "Warnings and Safety Precautions"

- Disconnect battery.

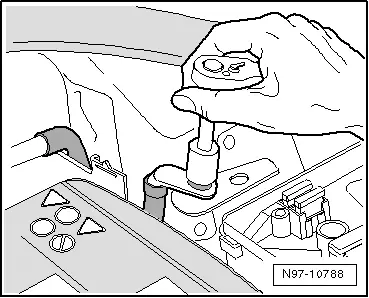

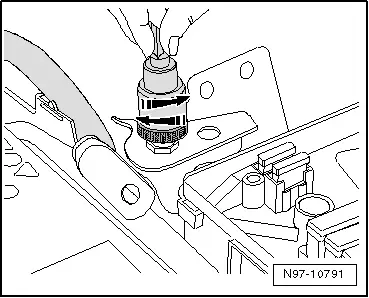

- Check the battery terminal clamp and the battery pole for corrosion or dirt.

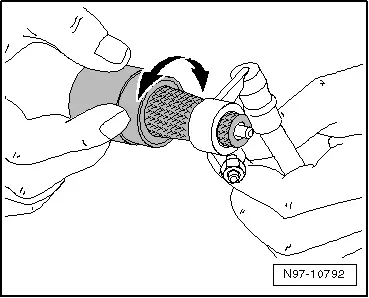

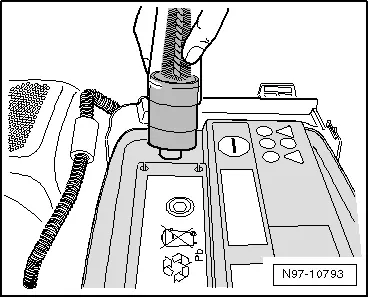

- The battery terminal clamp is cleaned with the battery terminal cleaner wire brush using circular motions.

- The battery terminal is cleaned with the bottom side of the terminal cleaner using circular motions.

WARNING

WARNING

Risk of injury. Prior to handling or servicing batteries, read, understand and observe the Warning and Safety Measures. Refer to → Chapter "Warnings and Safety Precautions"

- Reconnect the battery and tighten the terminals to the specified torque.

Note

Note

Optimal contact is ensured if the bolted components are tightened to the specified torque after cleaning.

Protecting

Caution

Caution

Missing protection leads to the electrical system damage.

Note

Note

- All threaded connections must be tightened to the specified torque.

- When applying protection, always use the accompanying hose on the protection container.

- Protection wax is used in the cool area.

- Cavity protection wax is used in the warm area.

- The protection material draws itself into the affected places by capillary action.

- Hold the injector under the wiring eyelet and spray all around the pins.

- Hold the injector above the wiring eyelet and spray all around the pins and wiring eyelet.