Audi Q3: General Information

Before beginning balancing, the following requirements must be fulfilled.

- Tire inflation pressure must be OK.

- The tire tread must not be worn down on one side and should be at least 4 mm deep.

- The tire must not have any flat spots.

It is not possible to balance a flat spot.

- The tires must not have any damage such as cuts, holes, foreign debris, etc.

- The suspension, steering, tie rods and damper must be in proper working order.

- A road test has been performed.

Road Test, Performing Before Balancing

If a vehicle comes to the workshop with the complaint vibration, a road test must be performed before balancing the wheels.

- That way, information about the type of vibration can be obtained.

- Observe at which speed range the disturbance takes place.

- Raise the vehicle on the platform immediately after the road test.

- Mark the installation position on the tire.

- Remove wheels from vehicle.

Caution

Caution

If brake pads are ceramics, wheel must not fall on brake disc, otherwise it will be irreparably damaged. To remove/install wheel, install long assembly pin instead of wheel bolts in top position (12:00 position) and short assembly pin in wheel bolt mounts for support. In this way, the wheel can glide on the assembly aids when removing/installing.

- Balance the wheels.

Stationary Balancing Machine

Special tools and workshop equipment required

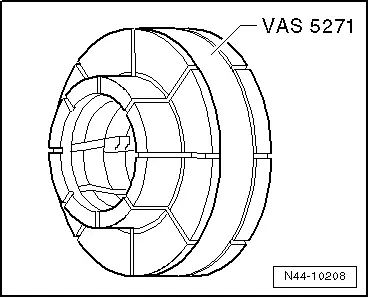

- Wheel Centering System Adapter -VAS5271-

- Wheel Balancer Clamping Adapter - 5 Lug -VAS6243-

Note

Note

Please keep in mind that cleanliness is the most important when balancing as well, just as for any other repairs you perform. Only then can a proper result be obtained!

Caution

Caution

The balance weights must be glued on so that rub against the brake caliper or the suspension.

- Tension wheel on balancing machine.

Note

Note

Wheels with a sensitive surface, glued-on wheel trim. Refer to → Chapter "Wheels with a Sensitive Surface, Glued-On Wheel Trim".

Note

Note

- Be careful not to scratch off the glued- on wheel trim on these rims.

- The surface of the wheel trim is very sensitive.

- The rim will have be replaced if the wheel trim is damaged.

- The wheel trim cannot be replaced.

Dirt and rust in the area of the contact surfaces and centering of the wheel distort the result.

- Clean contact surfaces, centering seat and wheel disc before tensioning wheel on balancing machine!

- Tension wheel with tire on balancing machine.

Caution

Caution

The balance weights must be glued on so that rub against the brake caliper or the suspension.

Note

Note

- To mount wheel on wheel balancer use, for example, the Wheel Centering System Adapter -VAS5271-.

- This way a 100% centering of the wheel and gentle mounting is possible!

- It is not possible to center it 100% on balancing machine with conical pensioners.

- With a deviation of 0.1 mm outside the center, there is an imbalance of 10 grams on the wheel/tire.

Note

Note

- Use Wheel Balancer Clamping Adapter - 5 Lug -VAS6243- to gently mount a wheel on the wheel balancer.

- This way improved balance results are attained and the surface of the rim is protected, for example, on chrome wheel rims.

Wheels with a Sensitive Surface, Glued-On Wheel Trim

Special tools and workshop equipment required

- Tension Plate -VAS6652-

- Pressure Bolt -VAS6652/1-

Note

Note

- Be careful not to scratch off the glued- on wheel trim on these rims.

- The surface of the wheel trim is very sensitive.

- The rim will have be replaced if the wheel trim is damaged.

- The wheel trim cannot be replaced.

Use only the Tension Plate -VAS6652- and the Pressure Bolt -VAS6652/1-.

Wheel/Tire Balancing Procedure

Note

Note

Wheels with a sensitive surface, glued-on wheel trim. Refer to → Chapter "Wheels with a Sensitive Surface, Glued-On Wheel Trim".

Caution

Caution

The balance weights must be glued on so that rub against the brake caliper or the suspension.

Note

Note

- Be careful not to scratch off the glued- on wheel trim on these rims.

- The surface of the wheel trim is very sensitive.

- The rim will have be replaced if the wheel trim is damaged.

- The wheel trim cannot be replaced.

- Let the wheel and tire rotate on the wheel balancer.

- Check the run of the characteristic lines on the sidewall of the tire in the area of the rim flange.

- Check the tire wear pattern while the wheel and tire are rotating.

Note

Note

In the event of one-sided wear, flat spots from braking or severe wear spots, smooth running cannot be achieved by balancing. In this case, the tire must be replaced.

- Check the run-out of the wheel and tire. If the wheel with tire runs untrue although there are no flat spots, a radial or lateral run-out may be the cause.

- Check wheel with tire for radial and lateral run-out, radial run-out (RR) and lateral runout (LR)!

- If the radial and lateral run-out are within the specified tolerance, balance the wheel and tire.

Note

Note

- Do not use more than 60 grams of weight per wheel.

- If more weight is necessary, a smoother running can achieved by matched mounting of the tire. Tires, matching. Refer to → Chapter "Matching".

- The display in the balancing machine should show 0 grams.

- Bolt the wheel to the vehicle.

Caution

Caution

If brake pads are ceramics, wheel must not fall on brake disc, otherwise it will be irreparably damaged. To remove/install wheel, install long assembly pin instead of wheel bolts in top position (12:00 position) and short assembly pin in wheel bolt mounts for support. In this way, the wheel can glide on the assembly aids when removing/installing.

- First tighten the bottom wheel bolt by hand to approximately 30 Nm.

- Now tighten the remaining wheel bolts diagonally also to about 30 Nm. This process centers the wheel on the wheel hub.

- Put the vehicle on its wheels.

- Now use a torque wrench to tighten the wheel bolts diagonally to the specified tightening specification.

- Carry out a road test.

Note

Note

- If a vibration is still detected during the road test, the cause may be due to tolerance in the wheel centering.

- The component tolerances of wheels and wheel hubs can be additive in unfavorable cases. Vibration can result from this. This can be eliminated using a finish balancer.