Audi Q3: Lower Control Arm, Removing and Installing

Special tools and workshop equipment required

- Locating Pins -T10096-

- Torque Wrench 1332 40-200Nm -VAG1332-

Removing

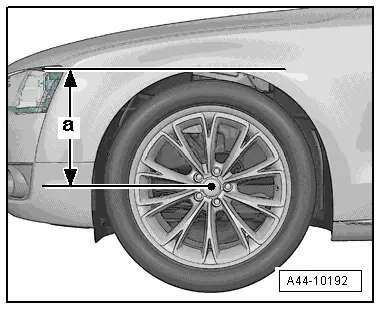

- Before starting work, determine the measurement -a-, for example with tape measure, from center of wheel to lower edge of wheelhouse.

Note

Note

Measurement must be performed in curb weight position (unloaded condition).

- Note the measured values. It will be required for tightening bolts/nuts.

- Remove the front wheel. Refer to → Chapter "Wheels and Tires".

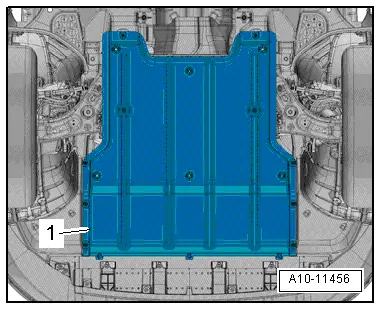

- Remove the noise insulation -1-. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

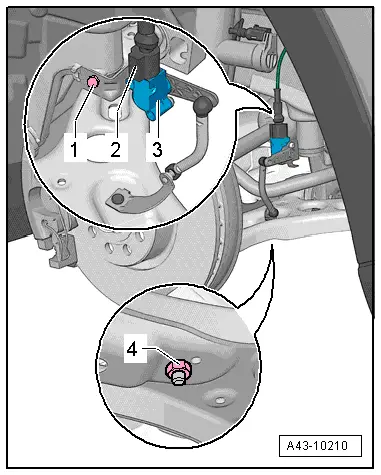

- If installed, remove the nut -4- and free up the coupling rod from the Left Front Level Control System Sensor -G78- or Right Front Level Control Sensor -G289--3-.

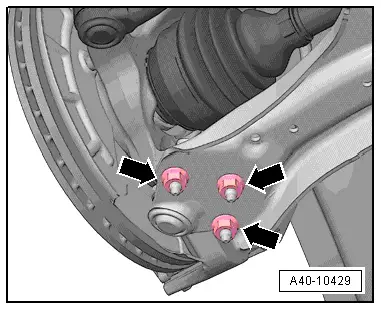

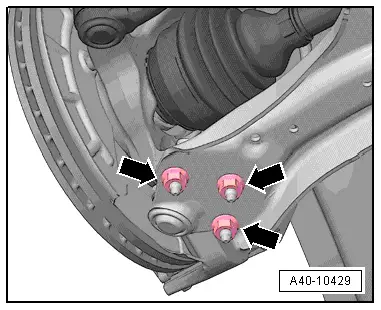

- Remove the nuts -arrows-.

- Remove both the wheel bearing housing and ball joint from the control arm.

Note

Note

Pay attention during the assembly work that the ball joint rubber boot is not damaged. If necessary protect the ball joint rubber boot against damage.

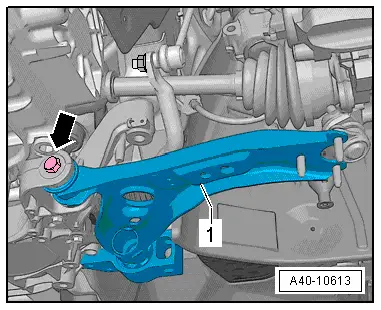

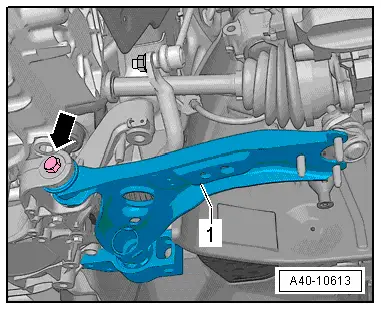

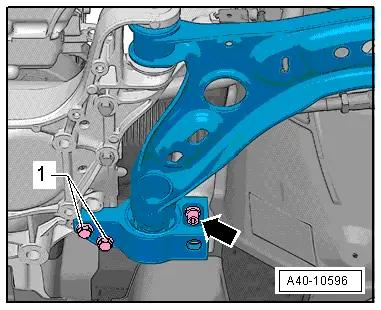

- Replace the bolt with the Locating Pins -T10096--arrow- and tighten to 20 Nm.

Caution

Caution

The locating pins may only be tightened to a maximum of 20 Nm, since otherwise the locating pin threads will be damaged.

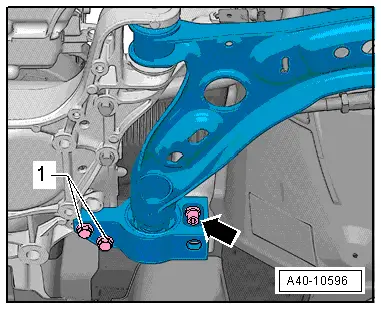

- Remove the bolts -1-.

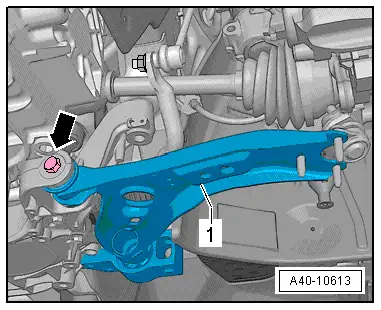

- Remove the bolt -arrow-.

Note

Note

On vehicles where the bolt -arrow- is not to be removed, the subframe must be lowered. Refer to → Chapter "Subframe, Lowering".

- Remove the control arm -1-.

Installing

Installation is reverse of removal, noting the following:

- Insert the control arm -1- with the mounting bracket into the subframe.

- Position the bolt -arrow- but do not tighten yet.

- Insert bolts -1- and tighten.

- Now replace Locating Pin -T10096- with a new bolt and tighten it.

- Bolt control arm tightly to ball joint -arrows-.

- Tighten the bolt -arrow- in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

Note

Note

Make sure the ball joint boot is not damaged or twisted.

- Install the front wheel. Refer to → Chapter "Wheels and Tires".

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

- On vehicles with electronically controlled damping, perform the function "Adapt the control position" with the Vehicle Diagnosis Tester.

- If the control position was reprogrammed and if the vehicle has lane assist, then it will then be necessary to calibrate the driver assistance systems front camera. Refer to → Chapter "Driver Assistance Systems Front Camera, Calibrating".

- On vehicles with level control system sensor, perform headlamp basic setting. Refer to → Electrical Equipment; Rep. Gr.94; Headlamp, Adjusting.

Mounting Bracket with Control Arm Bearing, Replacing

Special tools and workshop equipment required

- Press Piece - Guide Pin -VW439-

- Press Plate -VW401-

- Press Plate -VW402-

- Press Piece - Multiple Use -VW426-

- Installation Lubricant -G 294 421 A1-. Refer to the Parts Catalog

Pressing off mounting bracket with bearing for control arm:

- Control arm removed. Refer to → Chapter "Lower Control Arm, Removing and Installing".

Bonded rubber bushing is available as a replacement part only with the mounting bracket.

- Press the mounting bracket with bonded rubber bushing off the control arm.

Note

Note

Hold the control arm firmly when pressing out.

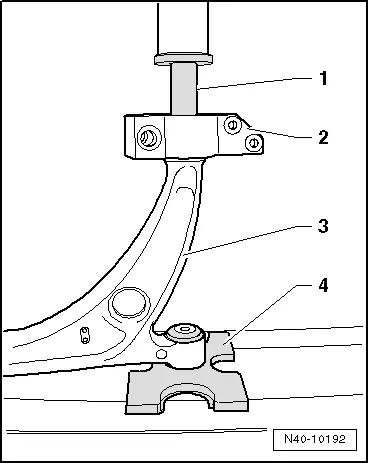

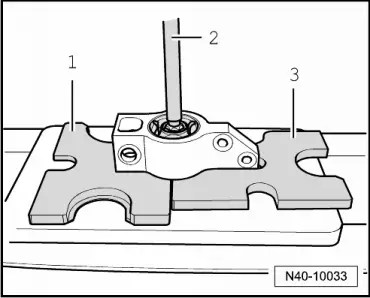

1 - Press Plate -VW401-

2 - Press Piece - Guide Pin -VW439-

3 - Press Plate -VW402-

Pressing on mounting bracket with bearing on control arm:

- Coat the control arm hex fitting with Installation Lubricant -G 294 421 A1-.

- Carefully press bearing onto control arm as far as stop.

1 - Press Piece - Multiple Use -VW426-

2 - Mounting bracket with bonded rubber bushing

3 - Control Arm

4 - Press Plate -VW401-