Audi Q3: Wheel Bearing Unit, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Loosen the drive axle threaded connection on the wheel side. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

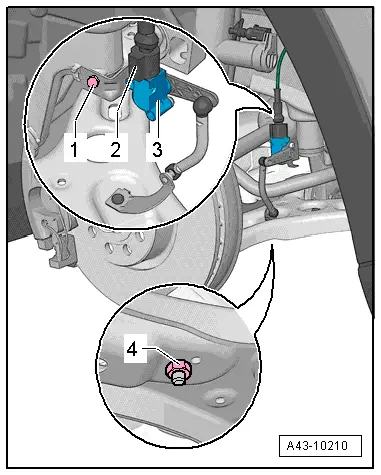

- If installed, remove the nut -4- and free up the coupling rod from the Left Front Level Control System Sensor -G78--3-.

- Remove the ABS speed sensor. Refer to → Brake System; Rep. Gr.45; Sensors; Right/Left Front ABS Wheel Speed Sensor G45/G47, Removing and Installing.

- Remove the brake rotor. Refer to → Brake System; Rep. Gr.46; Front Brakes; Brake Rotor, Removing and Installing.

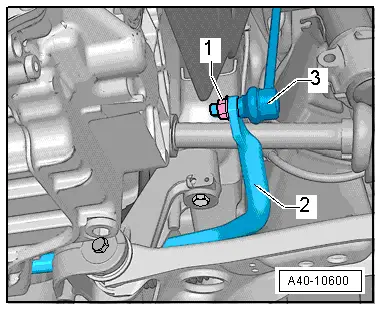

- Remove the nut -1-, remove the coupling rod -3- from the stabilizer bar -2- and pivot aside.

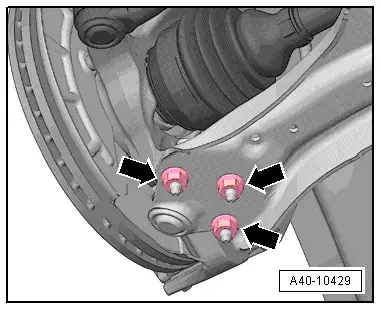

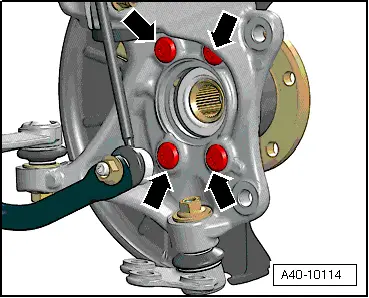

- Remove the nuts -arrows-.

- Remove the control arm from the ball joint.

- Remove the drive axle outer joint from the wheel hub.

- Secure drive axle to body using wire.

- Reconnect the ball joint in the control arm.

- Install the nuts -arrows-.

- Remove the bolts -arrows-.

- Remove wheel bearing unit from wheel bearing housing.

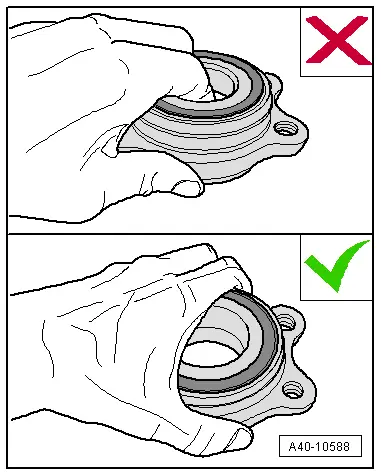

Caution

Caution

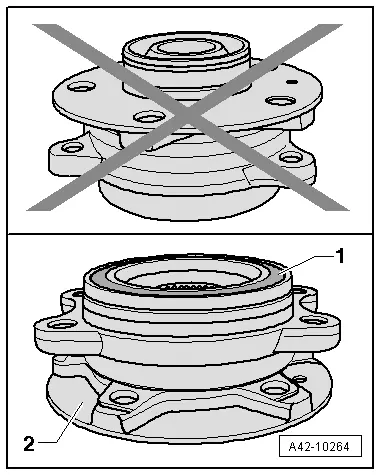

Avoid contaminating with dirt and damaging the seal when lifting, setting down/storing.

- The wheel bearing -1- must face up in order to remove the wheel bearing unit.

- Always set the wheel bearing unit down on the wheel hub -2-.

- Never reach into the inside when lifting the wheel bearing.

- Hold the wheel bearing only on the outside.

Installing

Install in reverse order of removal while noting the following:

- Install the brake caliper. Refer to → Brake System; Rep. Gr.46; Front Brakes; Brake Caliper, Removing and Installing.

Tightening Specifications

- Brake rotor.