Audi Q3: Overview - Drive Axle

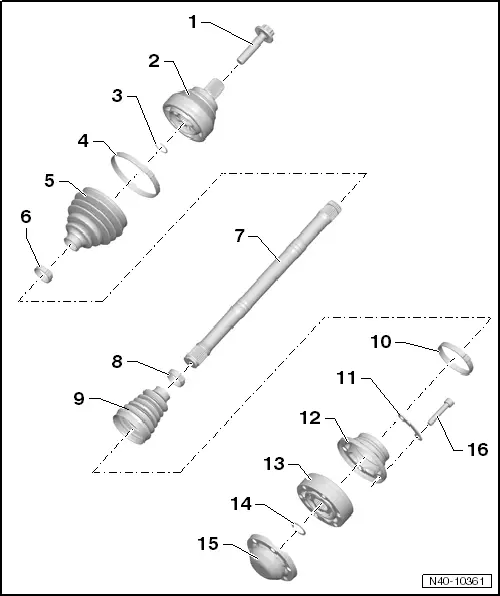

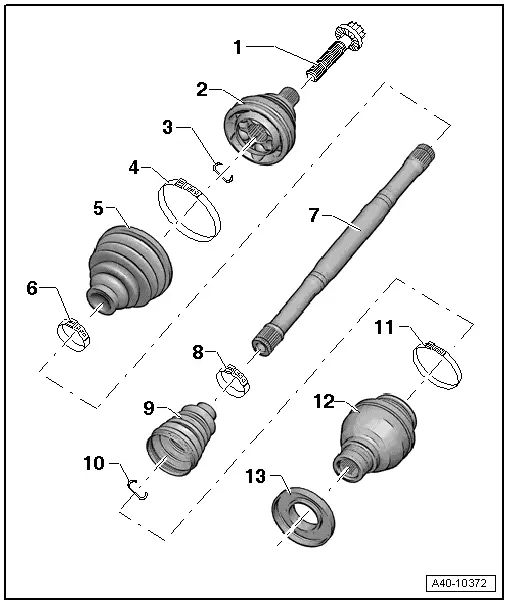

Overview - Drive Axle, Drive Axle with CV Joint VL107

1 - Bolt

- 200 Nm +180º

- Always replace if removed

- Loosening and tightening the twelve-point bolt → Chapter "Drive Axle Threaded Connection, Loosening and Tightening"

- Before installing, clean the threads in the CV joint with a tap.

2 - Outer CV Joint

- When installing the joint on the profile shaft, the splines on the profile shaft must be lightly coated with grease used in joint.

- Checking. Refer to → Chapter "Outer CV Joint, Checking".

- Removing. Refer to → Fig. "Removing the Outer CV Joint".

- Installing.

3 - Locking Ring

- Always replace if removed

- Insert in shaft groove

4 - Clamp

- Always replace if removed

- Tensioning.

5 - CV boot for outer CV joint

- Check for tears and scuffing

6 - Clamp

- Always replace if removed

- Tensioning.

7 - Profile Shaft

8 - Clamp

- Always replace if removed

- Tensioning.

9 - CV Boot for Inner CV Joint

- Check for tears and scuffing

10 - Clamp

- Always replace if removed

- Tensioning.

11 - Locking Plate

12 - Cover

- Always replace if removed

- Drive off CV joint using drift

- Adhesive surface must be free of oil and grease

- Apply sealant between the joint and cover. Refer to → Fig. "Coat the sealing surface on the cover with sealant and then install it.".

13 - Inner CV Joint

- Replace only as complete unit.

- When installing the joint on the profile shaft, the splines on the profile shaft must be lightly coated with grease used in joint.

- Checking. Refer to → Chapter "Inner CV Joint, Checking".

- Removing.

- Installing.

14 - Locking Ring

- Always replace if removed

- Remove and install using Circlip Pliers -VW161A-. Refer to → Fig. "Circlip, Removing and Installing".

15 - Cover

- Always replace if removed

- Drive off CV joint using drift

- Apply sealant between the joint and cover. Refer to → Fig. "Coat the sealing surface on the cover with sealant and then install it.".

16 - Bolt

- Pre-tightening specification: diagonal sequence to 10 Nm.

- M8 tightening specification: diagonal sequence to 40 Nm.

- M10 tightening specification: diagonal sequence to 70 Nm.

- Always replace if removed

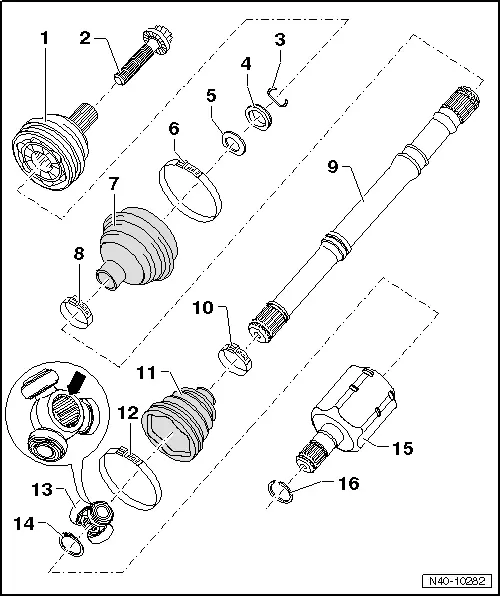

Overview - Drive Axle, Drive Axle with Triple Roller Joint AAR3300i, Mounted in Transmission

1 - Outer CV Joint

- Replace only as complete unit.

- Checking. Refer to → Chapter "Outer CV Joint, Checking".

- Removing.

- Installing: Drive onto shaft with plastic hammer until compressed circlip seats.

2 - Bolt

- 200 Nm +180º

- Always replace if removed

3 - Locking Ring

- Always replace if removed

- Insert in shaft groove

4 - Thrust Ring

- Not installed on all versions

- Installed position.

5 - Plate Spring

- Not installed on all versions

- Installed position.

6 - Clamp

- Always replace if removed

- Tensioning.

7 - CV Boot for CV Joint

- Check for tears and scuffing

- Material: polyelastomer

8 - Clamp

- Always replace if removed

- Tensioning.

9 - Drive Axle

10 - Clamp

- Always replace if removed

- Tensioning.

11 - CV Boot for Triple Roller Joint

- Check for tears and scuffing

12 - Clamp

- Always replace if removed

- Tensioning.

13 - Triple Roller Star with Rollers

The chamfer -arrow- points to drive axle splines.

14 - Locking Ring

- Always replace if removed

- Insert in shaft groove

15 - Joint

16 - Locking Ring

- Always replace if removed

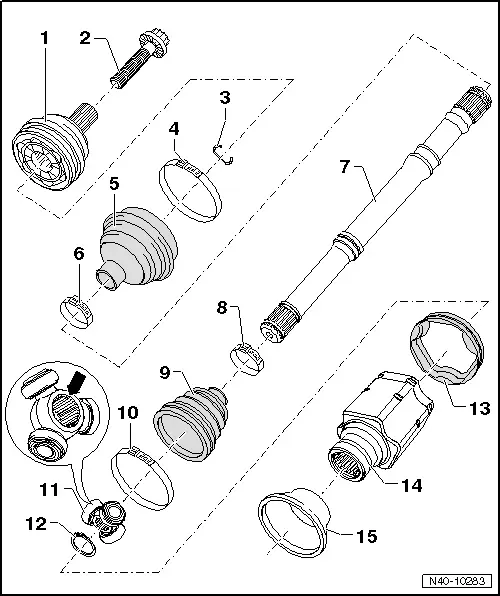

Overview - Drive Axle, Drive Axle with Triple Roller Joint AAR3300i, Mounted on Transmission Stub Shaft

1 - Outer CV joint

- Replace only as complete unit.

- Checking. Refer to → Chapter "Outer CV Joint, Checking".

- Removing. .

- Installing: Drive onto shaft with plastic hammer until compressed circlip seats.

2 - Bolt

- 200 Nm +180º

- Always replace if removed

3 - Locking Ring

- Always replace if removed

- Insert in shaft groove

4 - Clamp

- Always replace if removed

- Tensioning.

5 - CV Boot for CV Joint

- Check for tears and scuffing

- Material: polyelastomer

6 - Clamp

- Always replace if removed

- Tensioning.

7 - Drive Axle

8 - Clamp

- Always replace if removed

- Tensioning.

9 - CV Boot for Triple Roller Joint

- Check for tears and scuffing

10 - Clamp

- Always replace if removed

- Tensioning.

11 - Triple Roller Star with Rollers

The chamfer -arrow- points to drive axle splines.

12 - Locking Ring

- Always replace if removed

- Insert in shaft groove

13 - Adapter

14 - Joint

15 - Cap

- Remove.

- Installing.

Overview - Drive Axle, Drive Axle with CV Joint, Inserted with Inner Splines

1 - Bolt

- 200 Nm +180º

- Always replace if removed

- Before installing, clean the threads in the CV joint with a tap.

2 - Outer CV Joint

- Replace only as complete unit.

- Divide the grease between the ball paths.

- Checking. Refer to → Chapter "Outer CV Joint, Checking".

- Removing. Refer to → Fig. "Removing Outer CV Joint".

- Installing: Using a plastic hammer, drive onto the shaft as far as the stop

3 - Locking Ring

- Always replace if removed

- Insert in shaft groove

4 - Clamp

- Always replace if removed

- Tensioning.

5 - CV Boot

- Check for tears and scuffing

- Material: polyelastomer

6 - Clamp

- Always replace if removed

- Tensioning.

7 - Drive Axle

8 - Clamp

- Always replace if removed

- Tensioning.

9 - CV Boot for CV Joint

- Check for tears and scuffing

- Material: polyelastomer

10 - Locking Ring

- Always replace if removed

- Insert in shaft groove

11 - Clamp

- Always replace if removed

- Tensioning.

12 - CV Joint

- Replace only as complete unit.

- Divide the grease between the ball paths.

- Removing. Refer to → Fig. "Removing Outer CV Joint".

- Installing: Using a plastic hammer, drive onto the shaft as far as the stop

13 - Protective Cap

- Remove.

- Installing.

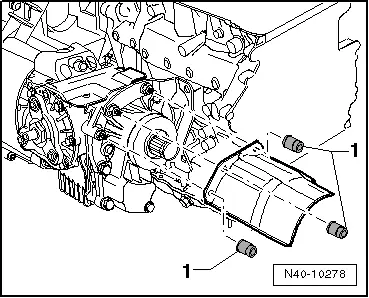

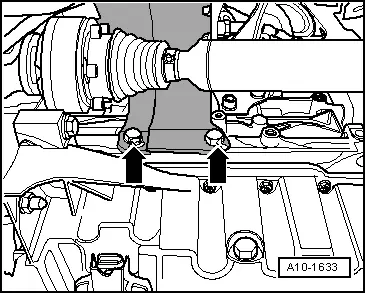

Overview - Drive Axle, Drive Axle Heat Shield

FWD Vehicles:

- Tighten the nuts -arrows- to 35 Nm.

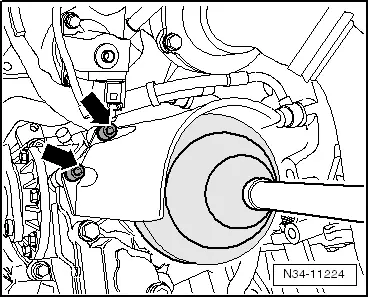

AWD vehicles version 1:

- Tighten the nuts -arrows- to 20 Nm.

AWD vehicles version 2:

- Tighten the nuts -1- to 20 Nm.