Audi Q3: Brake Lamp Switch, Removing and Installing

Note

Note

The Brake Lamp Switch -F-/Brake Pedal Switch -F63- is installed in the brake master cylinder.

Removing

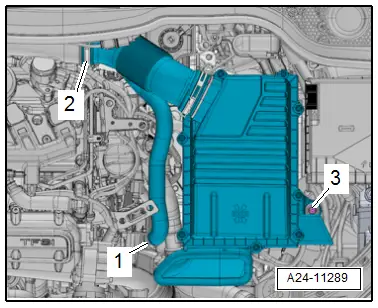

Audi RS Q3:

- Remove the air filter housing, refer to → Engine Mechanical, Fuel Injection and Ignition; Rep. Gr.24; Air Filter; Air Filter Housing, Removing and Installing.

Continuation for All Vehicles:

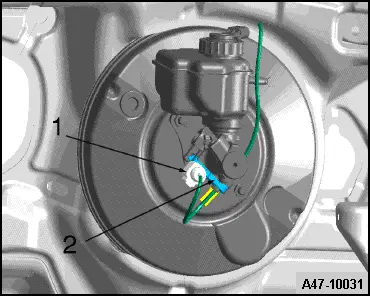

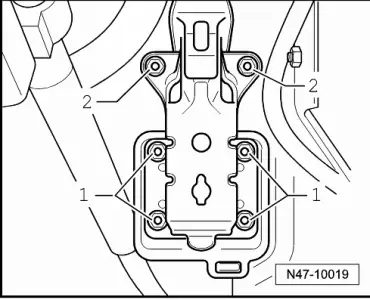

- Disconnect the connector -1-.

- Remove the brake lamp switch bolt -2-,

- Remove the brake lamp switch down from the brake master cylinder and remove it upward from the retaining tab.

Installing

Install in reverse order of removal. Note the following:

Note

Note

The brake light switch is not adjusted.

- Make sure that the brake lamp switch is seated correctly at top in the retaining tab.

- Tighten the brake lamp switch bolt.

Brake Booster, Removing and Installing

Special tools and workshop equipment required

- Brake Charger/Bleeder Unit -VAS5234- with Brake Bleeder Adapter -VAS5234/1-

- Sealing plugs from Repair Kit -1H0 698 311 A-

Removing

- Remove the vacuum in the brake booster by pressing the brake pedal repeatedly.

- Remove the air filter housing, refer to → Engine Mechanical, Fuel Injection and Ignition; Rep. Gr.24; Air Filter; Air Filter Housing, Removing and Installing or → Rep. Gr.23; Air Filter Housing, Removing and Installing.

Audi Q3:

- Remove the battery and the battery tray, refer to → Electrical Equipment; Rep. Gr.27; Battery; Battery Tray, Removing and Installing.

Continuation for All Vehicles:

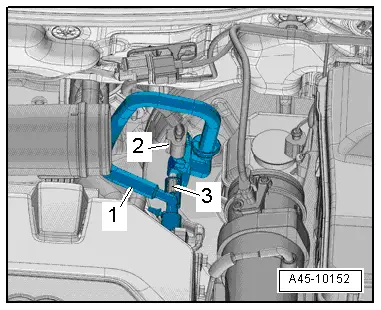

- Disconnect the connector -2-.

- Remove the vacuum line -1- from the vacuum pump and brake booster. Set it aside with the vacuum hose connected.

Note

Note

A vehicle with a 2.0L TFSI engine is shown in the illustration.

Vehicles with 2.0L TDI engine:

- Tie the air guide hose from the air filter housing to the turbocharger off to the side.

- Loosen the screw-type clamp on the air guide hose between the air guide pipe and turbocharger and turn it toward the rear.

Continuation for All Vehicles:

- Remove the brake master cylinder with the brake fluid reservoir, refer to → Chapter "Brake Master Cylinder, Removing and Installing".

- Disconnect the brake pedal from brake booster, refer to → Chapter "Brake Pedal, Removing from Brake Booster".

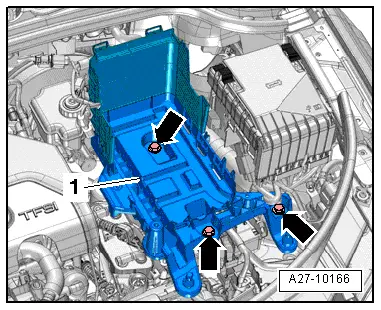

- Remove the nuts -1-.

- Remove the brake booster.

Note

Note

Ignore item -2-.

Installing

Install in reverse order of removal. Note the following:

- Attach the brake pedal to the brake booster, refer to → Chapter "Brake Pedal, Attaching to Brake Booster".

- Install the brake master cylinder, refer to → Chapter "Brake Master Cylinder, Removing and Installing".

- Bleed the brake system, refer to → Chapter "Hydraulic System, Bleeding".

- If applicable, bleed the clutch mechanism, refer to → Rep. Gr.30; Clutch Mechanism; Clutch Mechanism, Bleeding.

WARNING

WARNING

Risk of accident!

Make sure the brakes are working correctly before driving the vehicle.

Tightening Specifications

- Battery tray and battery, refer to → Electrical Equipment; Rep. Gr.27; Battery; Overview - Battery.