Audi Q3: CV Joint, Servicing, Drive Axle with CV Joint VL107

Special tools and workshop equipment required

- Clamping Pliers -VAG1682A-

- Circlip Pliers -VW161A-

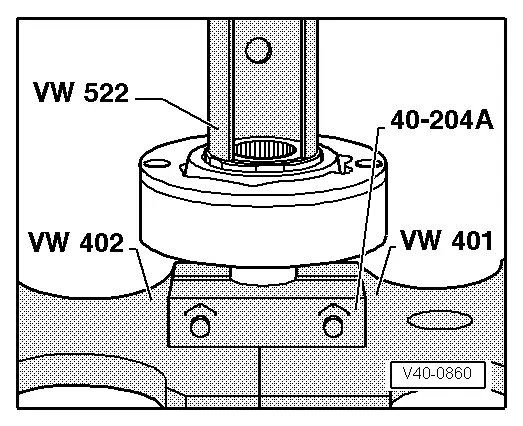

- Press Plate -VW401-

- Press Plate -VW402-

- Press Piece - Rod -VW408A-

- CV Joint Press Sleeve -VW522-

- Press Block -40-204A-

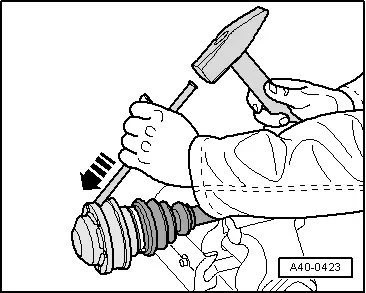

Removing the Outer CV Joint

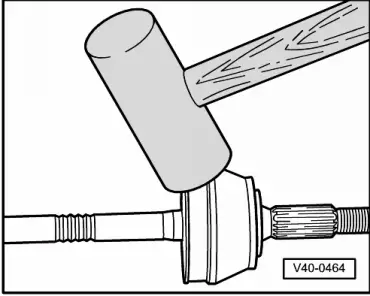

- Remove the CV joint from the drive axle by hitting it with a light alloy hammer.

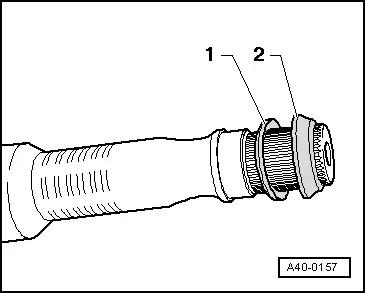

If installed, installation position of spacer ring and plate spring on outer joint.

1 - Plate Spring

2 - Spacer ring (plastic)

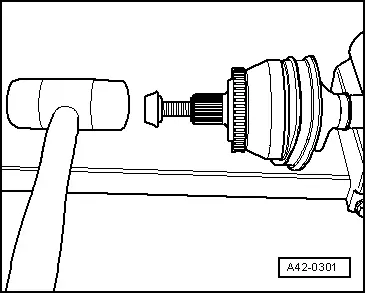

Outer CV Joint with Bolt, Installing

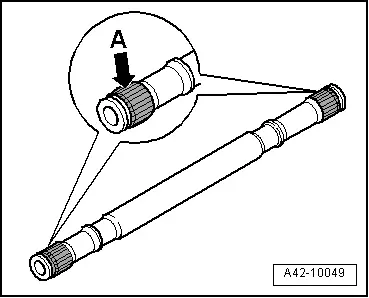

- Before installing joint piece, splines -A- must be lightly coated with grease used in joint.

- Install the old bolt in the joint as shown in the illustration.

- Drive joint onto shaft with plastic hammer until circlip engages.

Removing the Inner CV Joint

Removing the Cover

- Drive cover down with copper or brass drift.

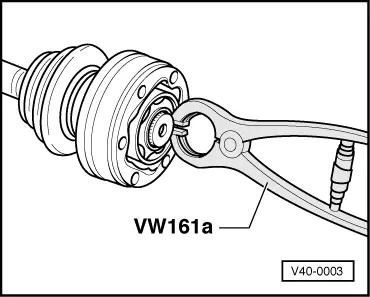

Circlip, Removing and Installing

- Drive out CV joint boot with a drift.

- Support ball hub when pressing off.

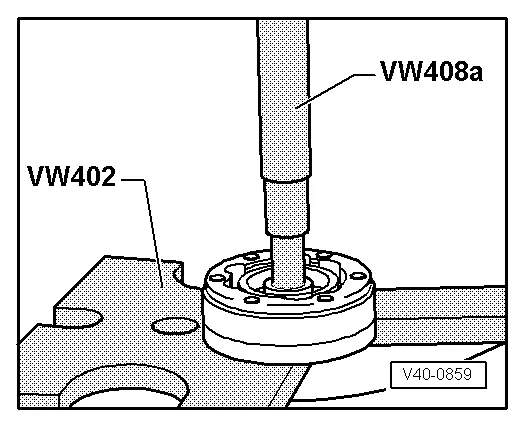

Pressing on inner CV joint

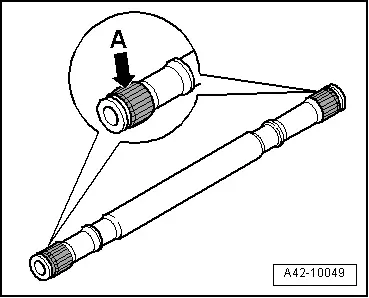

- Before installing joint piece, splines -A- must be lightly coated with grease used in joint.

- Press on joint until stop.

- Install circlip.

Note

Note

Chamfer on inner diameter of ball hub (splines) must face the contact shoulder on the drive axle.

Coat the sealing surface on the cover with sealant and then install it.

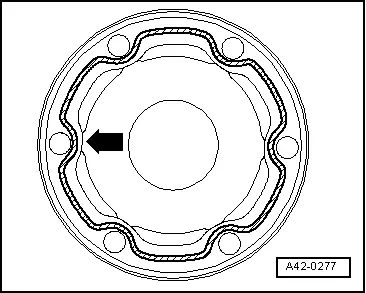

- Apply sealant - shown as the cross-hatched area- onto the clean cover surface.

- Sealant bead: apply a continuous bead with a 2 to 3 mm diameter in cross-hatched area and inside the holes -arrow- as shown.

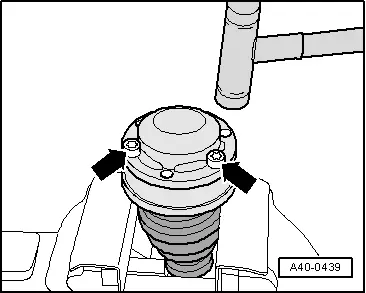

- Align new cover with bolts -arrows- to bolt holes.

It must be aligned exactly because it cannot be aligned after driving on.

- Drive cover on with a plastic hammer.

- Wipe away any sealant leaking out.

Rubber CV Boot, Venting

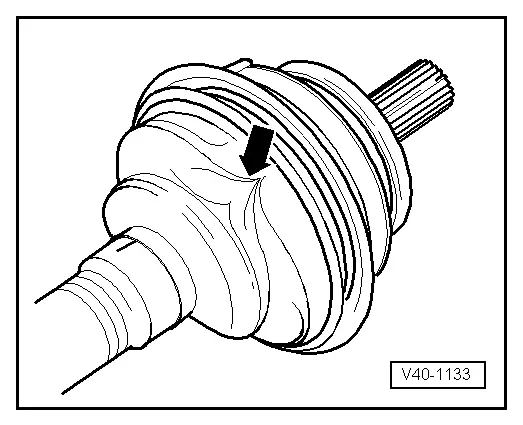

The CV boot is frequently pressed in when placed on the CV joint body. This creates a vacuum in the CV boot, which pulls a fold inward when the car is driven -arrow-.

Therefore, note the following:

- Before clamping the clamping sleeves, balance the pressure by raising the CV boot.

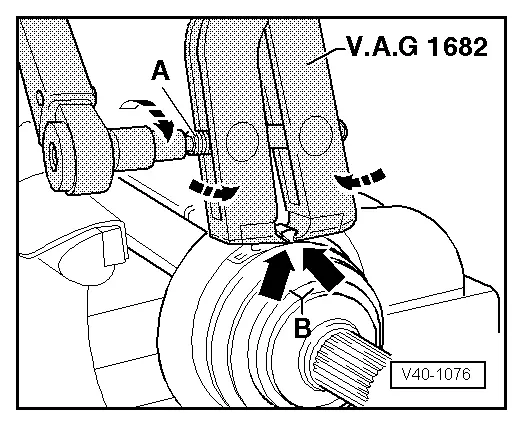

Stainless Steel Clamps for Hytrel Protective Joint Boots, Tensioning

- Position the Clamping Pliers -VAG1682A- as shown in illustration. When doing this, make sure that edges of Clamping Pliers -VAG1682A- are seated in the corners -arrows B- of clamp.

- Tighten the Clamping Pliers -VAG1682A- by turning spindle -A- using a torque wrench (do not tilt the Clamping Pliers -VAG1682A-).

- Tightening specification: 20 Nm

Note

Note

- Make sure the threads on the spindle on the pliers move easily. Lubricate with MoS2 grease, if necessary.

- If the thread is tight, for example it is dirty, the required tensioning force for the hose clamp will not be achieved in spite of correct torque specification settings.