Audi Q3: Stabilizer Bar

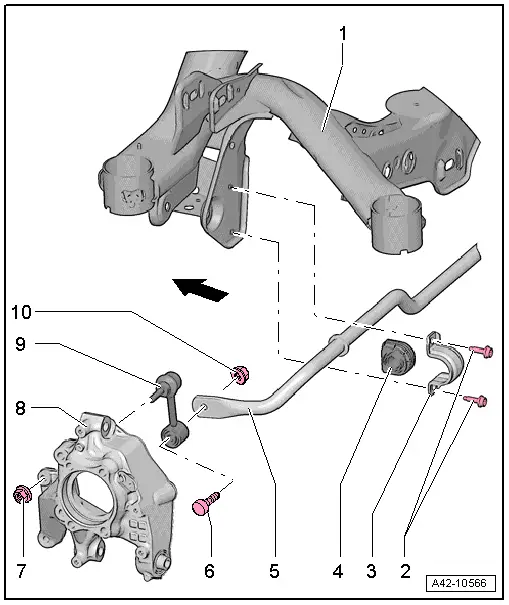

Overview - Stabilizer Bar

1 - Subframe

2 - Bolt

- 25 Nm + 45º

- Always replace if removed

- Install evenly

3 - Clamp

4 - Bearing

- Always replace the rubber mounts on both sides of vehicle

5 - Stabilizer Bar

- Removing and installing. Refer to → Chapter "Stabilizer Bar, Removing and Installing".

6 - Bolt

7 - Nut

- 40 Nm

- Counterhold at the inner multipoint fitting when tightening

8 - Wheel Bearing Housing

9 - Coupling Rod

10 - Nut

- 40 Nm

- Counterhold at the inner multipoint fitting of the bolt -item 6-, when tightening

- Tighten in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

Stabilizer Bar, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

Removing

- Remove the rear wheels. Refer to → Chapter "Wheels and Tires".

Note

Note

The following work steps are described for the left side of the vehicle. These work steps also apply simultaneously for right side of vehicle.

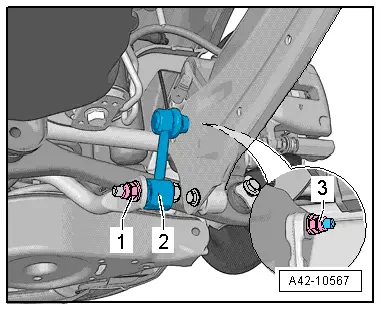

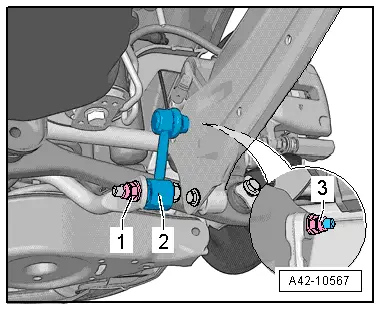

- Remove the nut -1- and pull the coupling rod -2- out of the stabilizer bar.

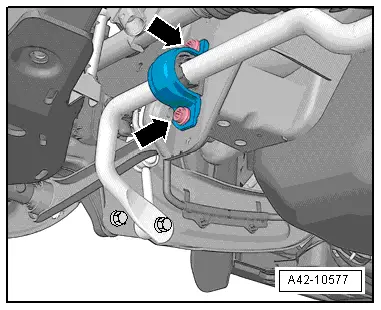

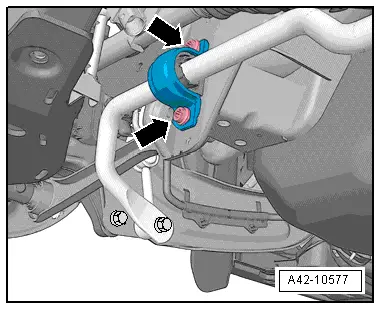

- Remove the bolts -arrows- for the stabilizer bar clamp.

- If the upper bolt for the stabilizer bar clamp cannot be removed due to the driveshaft, perform the following steps:

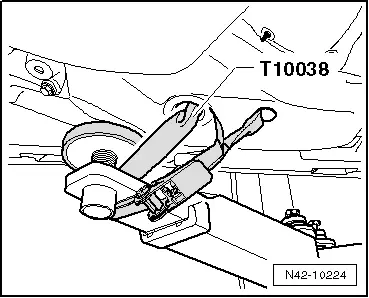

- Secure both sides of the vehicle on the hoist arms using Tensioning Straps -T10038-.

WARNING

WARNING

The vehicle could slide off the hoist if it is not secured.

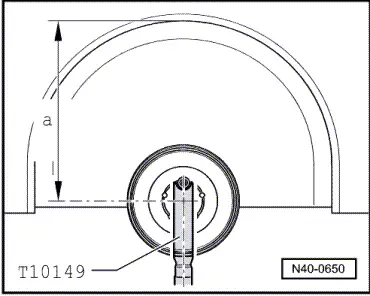

- Install Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149- with wheel bolt on wheel hub.

- Lift the wheel hub using the Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149- and Engine and Gearbox Jack -VAS6931- far enough until the bolts on the right stabilizer bar clamp are accessible.

- Remove the stabilizer bar.

Installing

Installation is reverse of removal, noting the following:

- Tighten the bolts -arrows- for stabilizer clamp uniformly.

- Counterhold at the inner multipoint fitting when tightening the coupling rod bolts.

- Mount the rear wheels. Refer to → Chapter "Wheels and Tires".

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

Coupling Rod, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

Removing

- Remove the rear wheel. Refer to → Chapter "Wheels and Tires".

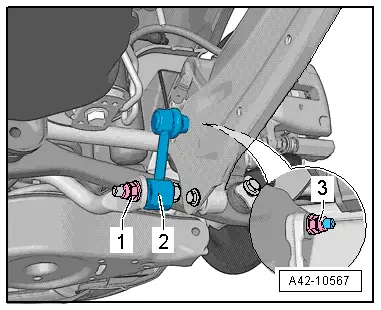

- Remove the nuts -1 and 3- and pull the coupling rod -2- out of the stabilizer bar and trailing arm.

Installing

Installation is reverse of removal, noting the following:

- Insert the coupling rod -2-, install the nuts -1 and 3- and tighten in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- When tightening the nuts -1 and 3-, counterhold at the inner multipoint fitting of the bolts.

- Mount the rear wheel. Refer to → Chapter "Wheels and Tires".