Audi Q3: Upper Transverse Link, Removing and Installing

Upper Transverse Link, Removing and Installing, FWD Vehicles

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Measure dimension from center of wheel to lower edge of wheel housing. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Remove the coil spring. Refer to → Chapter "Spring, Removing and Installing".

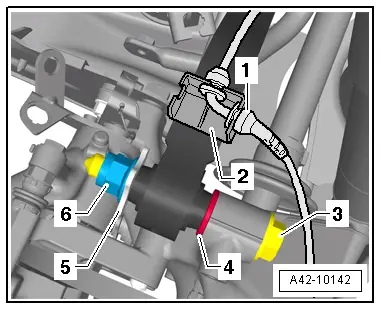

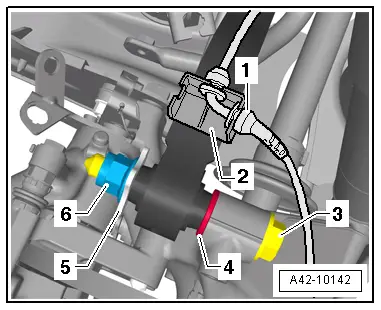

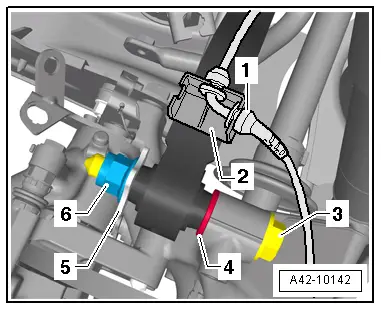

- Disengage the line -1- from the bracket -2-.

- Remove the nut -6- and the washer -5-.

- Remove the bolt -3- and washer -4-.

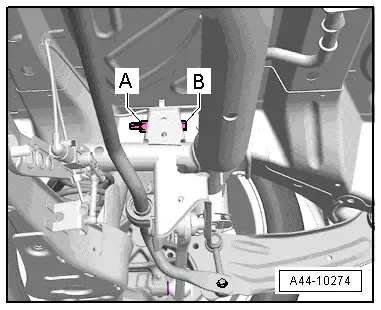

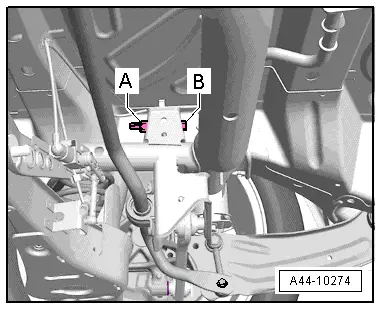

- Mark the position of eccentric screw -B- to the subframe using, for example, a felt-tip marker.

- Remove the nut -A- and the eccentric screw -B-.

- Remove upper transverse link.

Installing

Installation is reverse of removal, noting the following:

- The transverse link threaded connection may only be fastened if the dimension between the wheel hub center and the lower edge of the wheel housing that was measured before assembly is reached. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Note the applied marking of the eccentric screw -B- to the subframe.

Note

Note

The washer -5- must be installed so that there is a gap between the washer and the brake shield.

- Install the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

Upper Transverse Link, Removing and Installing, AWD Vehicles

Special tools and workshop equipment required

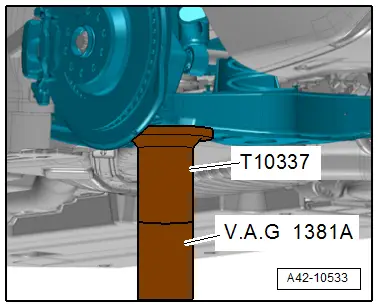

- Engine/Gearbox Jack - Gearbox Support -T10337-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Engine and Gearbox Jack -VAS6931-

Removing

- Measure dimension from center of wheel to lower edge of wheel housing. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Remove the rear wheel. Refer to → Chapter "Wheels and Tires".

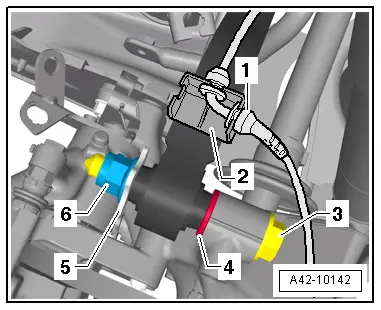

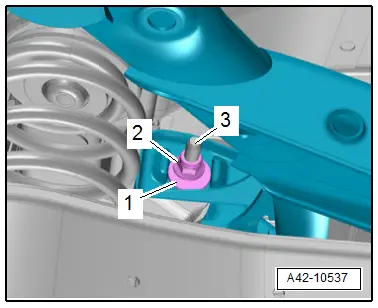

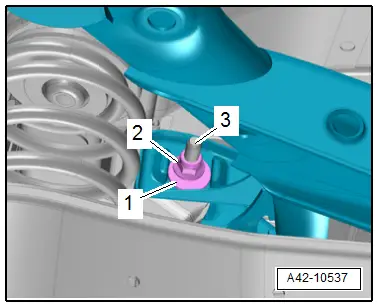

- Disengage the right and left wire -1- from the bracket -2-.

- Mount the Engine/Gearbox Jack - Gearbox Support -T10337- onto the Engine and Gearbox Jack -VAS6931- and attach to the lower control arm.

- Remove the nut -6- and then remove the bolt -3- with the washers -4 and 5- by lifting the stub axle carrier slightly using the Engine and Gearbox Jack -VAS6931-.

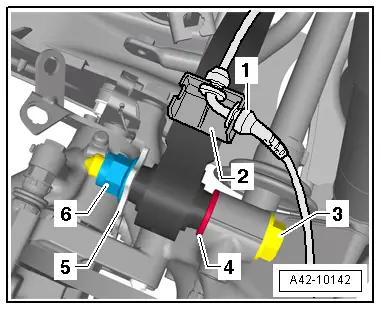

- Mark the position of eccentric washer -1- to subframe on both sides, using, for example, a felt-tip marker.

- Remove the nut -2- and the eccentric screw -3-.

- Remove upper transverse link.

Installing

Installation is reverse of removal, noting the following:

- The transverse link threaded connection may only be fastened if the dimension between the wheel hub center and the lower edge of the wheel housing that was measured before assembly is reached. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Note the applied marking of eccentric washer -1- to the subframe.

Note

Note

The washer -5- must be installed so that there is a gap between the washer and the brake shield.

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".