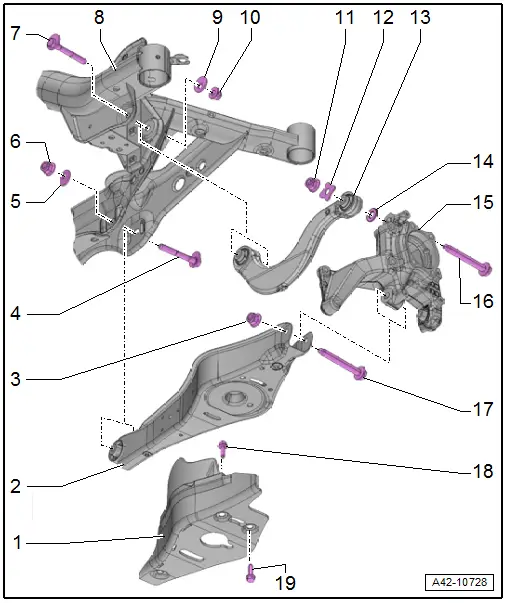

Audi Q3: Overview - Transverse Link

Audi Q3 (8U) 2011-2018 Service Manual / Chassis / Suspension, Wheels, Steering / Rear Suspension / Overview - Transverse Link

1 - Stone Chip Protection

- For allocation. Refer to the Parts Catalog.

2 - Lower Transverse Link

- Removing and installing. Refer to → Chapter "Lower Transverse Link, Removing and Installing, FWD Vehicles".

3 - Nut

- 90 Nm + 90º

- Always replace if removed

- Always tighten threaded connections in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

4 - Eccentric Screw

- Do not turn more than 90º right or left (that is smallest to largest possible adjustment)

- For toe setting

- Perform a vehicle alignment after loosening. Refer to → Chapter "Axle Alignment Procedure".

5 - Eccentric Washer

- Inner bore with tab

6 - Nut

- 95 Nm

- Always replace if removed

- Always tighten threaded connections in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

7 - Eccentric Screw

- Do not turn more than 90º right or left (that is smallest to largest possible adjustment)

- For camber setting

- Perform a vehicle alignment after loosening. Refer to → Chapter "Axle Alignment Procedure".

8 - Subframe

- Removing and installing. Refer to → Chapter "Subframe, Removing and installing, FWD Vehicles".

9 - Eccentric Washer

- Inner bore with tab

10 - Nut

- 95 Nm

- 80 Nm. This tightening specification only applies in conjunction with Insert Tool - 18mm -T10179-

- Always replace if removed

- Always tighten threaded connections in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

11 - Nut

- For tightening specifications, see bolt -16-

- Always replace if removed

12 - Washer

13 - Upper Transverse Link

- Removing and installing. Refer to → Chapter "Upper Transverse Link, Removing and Installing, FWD Vehicles".

14 - Washer

15 - Wheel Bearing Housing

16 - Bolt

- 130 Nm + 90º

- Always replace if removed

- Always tighten threaded connections in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

17 - Bolt

- Always replace if removed

18 - Expanding Rivet

- Quantity: 2

19 - Bolt

- 8 Nm

- Quantity: 3

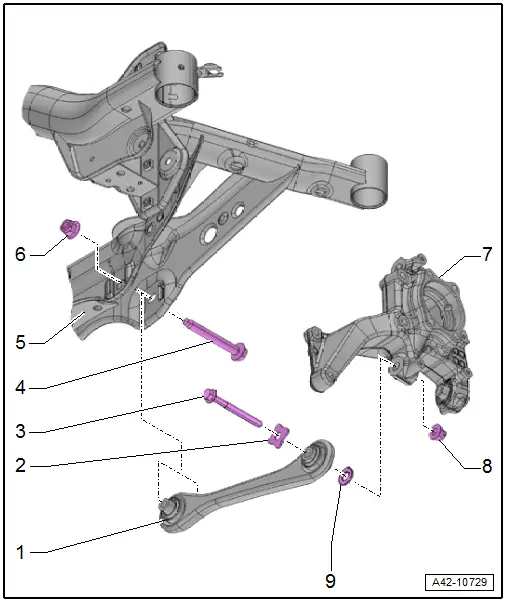

Overview - Tie Rod

1 - Tie Rod

- Removing and installing. Refer to → Chapter "Tie Rod, Removing and Installing, FWD Vehicles".

2 - Washer

3 - Bolt

- 130 Nm + 90º

- Always replace if removed

- Always tighten threaded connections in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

4 - Bolt

- Always replace if removed

5 - Subframe

- Removing and installing. Refer to → Chapter "Subframe, Removing and installing, FWD Vehicles".

6 - Nut

- 90 Nm + 90º

- Always replace if removed

7 - Wheel Bearing Housing

8 - Nut

- Always replace if removed

9 - Washer

READ NEXT:

Upper Transverse Link, Removing and Installing

Upper Transverse Link, Removing and Installing

Upper Transverse Link, Removing and Installing, FWD Vehicles

Special tools and workshop equipment

required

Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Measure dimension from cente

Lower Transverse Link, Removing and Installing

Lower Transverse Link, Removing and Installing

Lower Transverse Link, Removing and Installing, FWD Vehicles

Special tools and workshop equipment

required

Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Measure dimension from cente

Tie Rod, Removing and Installing

Tie Rod, Removing and Installing

Tie Rod, Removing and Installing, FWD Vehicles

Special tools and workshop equipment

required

Torque Wrench 1331 5-50Nm -VAG1331-

Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Meas

SEE MORE:

Wheel Bearing Housing Bonded Rubber Bushing, Replacing

Wheel Bearing Housing Bonded Rubber Bushing, Replacing

Wheel Bearing Housing Bonded Rubber Bushing, Replacing, FWD Vehicles

Special tools and workshop equipment

required

Bearing Installer - Control Arm -3346-

Bearing Installer - Carrier Bearing -3350-

Fitting Sleeve -3378-

Torque Adapter -3390-

Torque Wrench 1332 40-200Nm -VAG1332-

Rem

Rearview camera and peripheral cameras

Rearview camera and peripheral cameras

Introduction

Applies to: vehicles with rearview camera/peripheral cameras

Fig. 113 Orientation line display when parking

Depending on the vehicle equipment, a rearview

camera or multiple peripheral cameras may be

available.

The rearview camera helps you to park or maneuver

using the orientation li

© 2019-2025 Copyright www.auq3.net