Audi Q3: Wheel Bearing Housing, Removing and Installing

Wheel Bearing Housing, Removing and Installing, FWD Vehicles

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Measure dimension from center of wheel to lower edge of wheel housing. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

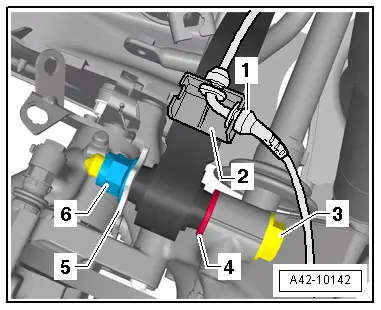

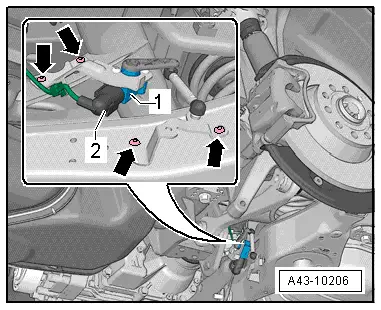

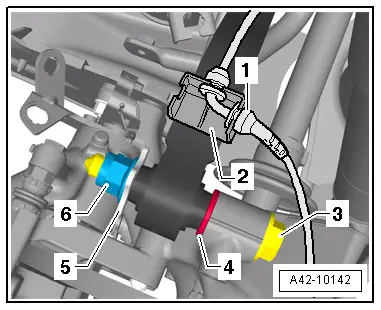

Vehicles with level control system sensor

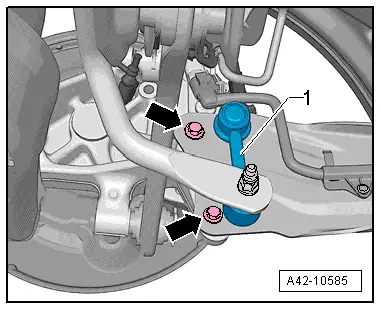

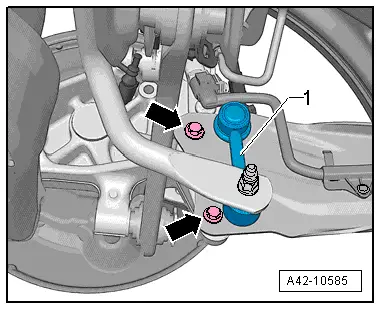

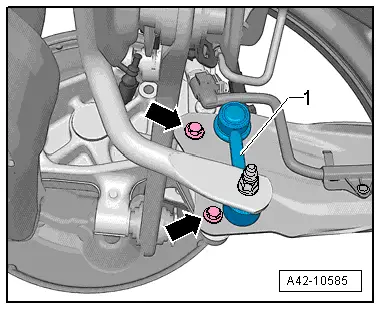

- Remove the bolts -lower arrows-.

Continuation for all vehicles

- Remove the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- Remove the ABS speed sensor from the wheel bearing housing. Refer to → Brake System; Rep. Gr.45; Sensors; Right/Left Rear ABS Wheel Speed Sensor G44/G46, Removing and Installing.

- Remove the brake shield. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Shield, Removing and Installing.

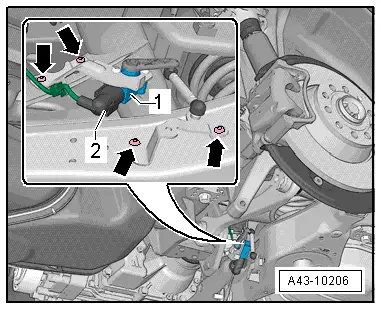

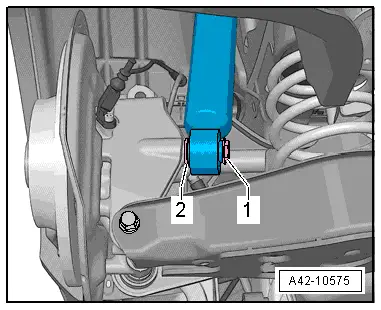

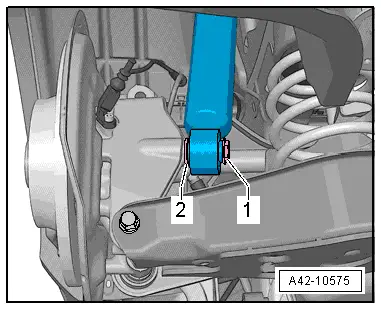

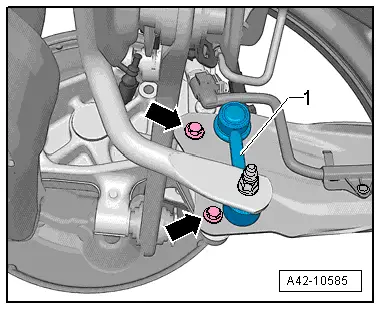

- Remove the bolt -1- and the washer -2-.

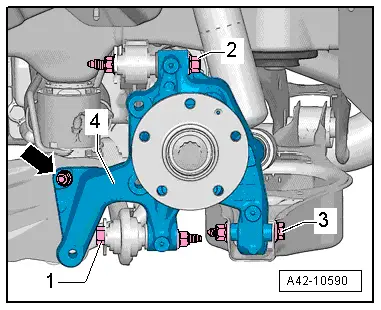

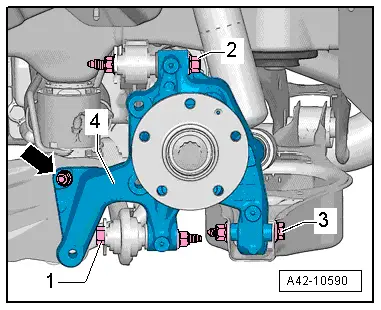

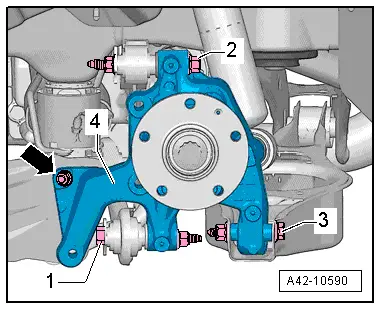

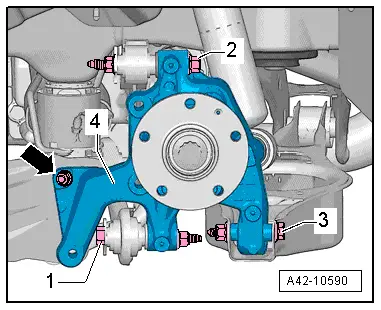

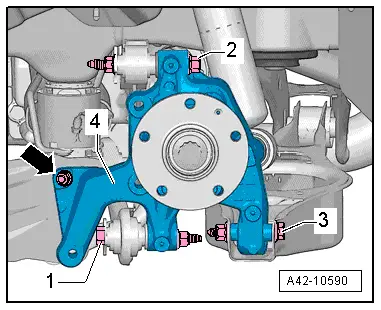

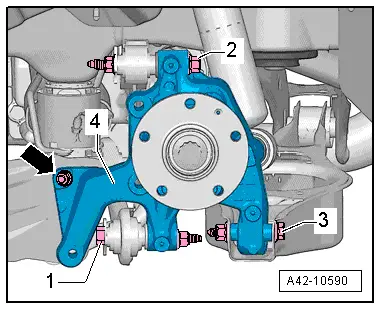

- Remove bolt for tie rod -1-, upper control arm -2- and lower control arm -3- from wheel bearing housing -4-.

- Remove the coupling rod -arrow- from the wheel bearing housing.

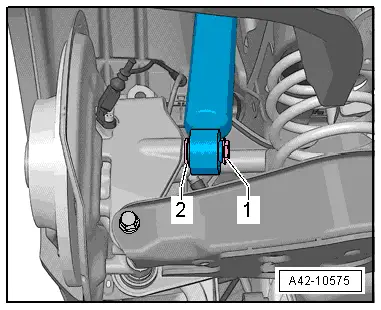

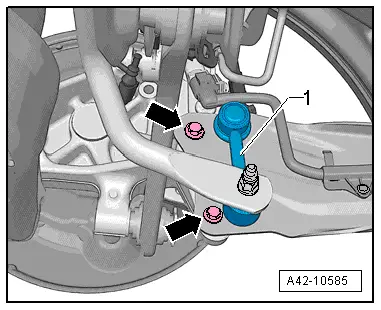

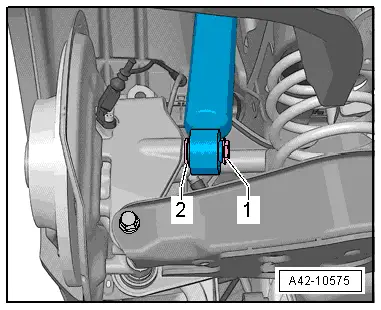

- Remove the coupling rod from the trailing arm -1-.

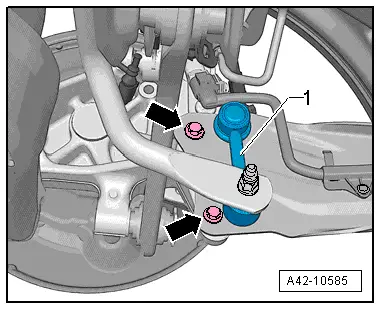

- Hold wheel bearing housing tightly and remove the bolts -arrows-.

- Pull coupling rod -1- out of trailing arm.

- Remove the wheel bearing housing.

Installing

Installation is reverse of removal, noting the following:

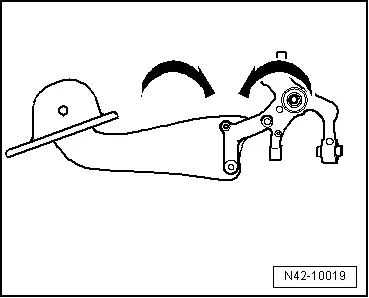

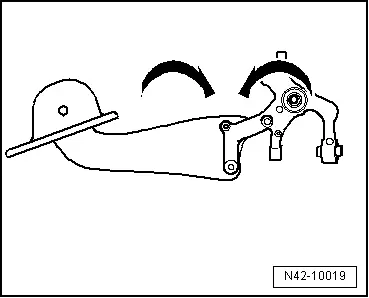

Threaded connection of trailing link/wheel bearing housing must only be tightened when all other components (spring and strut always) of the respective wheel suspension have been already assembled. To tighten, suspension must be unloaded. Only now do the trailing link and wheel bearing housing move into the position required -arrows-.

Always perform the following work in the sequence given!

- Install the bolt for tie rod -1-, upper control arm -2- and lower control arm -3- hand-tight.

- Hand-tighten the coupling rod -arrow- to wheel bearing housing -4-.

- Install the bolts -arrows- and insert the coupling rod -1- into trailing arm.

- Tighten the bolt -1- with the washer -2-.

Bolting at wheel bearing housing may occur only when the dimension "a" has been obtained! Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Install the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- Tighten the bolt for tie rod -1-, upper control arm -2- and lower control arm -3-.

- Tighten the coupling rod nut -arrow-.

Note

Note

The washer -5- must be installed so that there is a gap between the washer and the brake shield.

- Tighten the bolts -arrows-.

Install in reverse order of removal while noting the following:

- Install the brake caliper. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Caliper, Removing and Installing.

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

- On vehicles with electronically controlled damping, perform the function "Adapt the control position" with the Vehicle Diagnosis Tester.

- If the control position was reprogrammed and if the vehicle has lane assist, then it will then be necessary to calibrate the driver assistance systems front camera. Refer to → Chapter "Driver Assistance Systems Front Camera, Calibrating".

- On vehicles with level control system sensor, perform headlamp basic setting. Refer to → Electrical Equipment; Rep. Gr.94; Headlamp, Adjusting.

Wheel Bearing Housing, Removing and Installing, AWD Vehicles

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Measure dimension from center of wheel to lower edge of wheel housing. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Loosen the outer drive axle threaded connection. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

Vehicles with level control system sensor

- Remove the bolts -lower arrows-.

Continuation for all vehicles

- Remove the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- Remove the brake shield. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Shield, Removing and Installing.

- Remove the ABS speed sensor from the wheel bearing housing. Refer to → Brake System; Rep. Gr.45; Sensors; Right/Left Rear ABS Wheel Speed Sensor G44/G46, Removing and Installing.

- Remove the bolt -1- and the washer -2-.

- Remove bolt for tie rod -1-, upper control arm -2- and lower control arm -3- from wheel bearing housing -4-.

- Remove the coupling rod from the wheel bearing housing -arrow-.

- Pull coupling rod -1- out of trailing arm.

- Hold wheel bearing housing tightly and remove the bolts -arrows-.

- Remove the wheel bearing housing.

Installing

Installation is reverse of removal, noting the following:

Threaded connection of trailing link/wheel bearing housing must only be tightened when all other components (spring and strut always) of the respective wheel suspension have been already assembled. To tighten, suspension must be unloaded. Only now do the trailing link and wheel bearing housing move into the position required -arrows-.

Always perform the following work in the sequence given!

- Install the bolt for tie rod -1-, upper control arm -2- and lower control arm -3- hand-tight.

- Hand-tighten the coupling rod -arrow- to wheel bearing housing -4-.

- Install the bolts -arrows- and insert the coupling rod -1- into trailing arm.

- Tighten the bolt -1- with the washer -2-.

Bolting at wheel bearing housing may occur only when the dimension "a" has been obtained! Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Install the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- Tighten the bolt for tie rod -1-, upper control arm -2- and lower control arm -3-.

- Tighten the nut -arrow- for the coupling rods.

Note

Note

The washer -5- must be installed so that there is a gap between the washer and the brake shield.

- Tighten the bolts -arrows-.

Install in reverse order of removal, note the following:

- Install the brake caliper. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Caliper, Removing and Installing.

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

- On vehicles with electronically controlled damping, perform the function "Adapt the control position" with the Vehicle Diagnosis Tester.

- If the control position was reprogrammed and if the vehicle has lane assist, then it will then be necessary to calibrate the driver assistance systems front camera. Refer to → Chapter "Driver Assistance Systems Front Camera, Calibrating".

- On vehicles with level control system sensor, perform headlamp basic setting. Refer to → Electrical Equipment; Rep. Gr.94; Headlamp, Adjusting.