Audi Q3: Wheel Bearing Unit, Removing and Installing

Wheel Bearing Unit, FWD, Removing and Installing

Special tools and workshop equipment required

- Puller - Grease Cap -VW637/2-

- Camshaft Installer Kit - Sleeve -3241/4- from the Seal Installer - Camshaft Installer Kit -3241-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Torque Wrench -VAG1410-

- Socket - Xzn 18 -T10162-

Removing

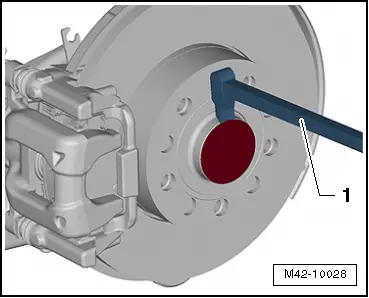

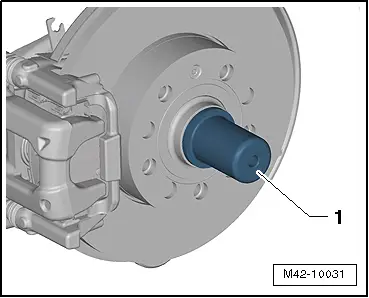

- Loosen the dust cap from seat by tapping lightly on claw of Puller - Grease Cap -VW637/2--1-.

- Remove the dust cap using the Puller - Grease Cap -VW637/2--1-.

- Remove the brake caliper with the brake carrier and secure it to the body using wire. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Caliper, Removing and Installing.

Note

Note

Do not allow brake caliper to hang from brake line.

- Remove the Phillips head bolt for the brake rotor and then remove the brake rotor.

- Remove the internal multipoint bolt with the Socket - Xzn 18 -T10162-.

- Remove the wheel bearing unit from the axle stub.

Caution

Caution

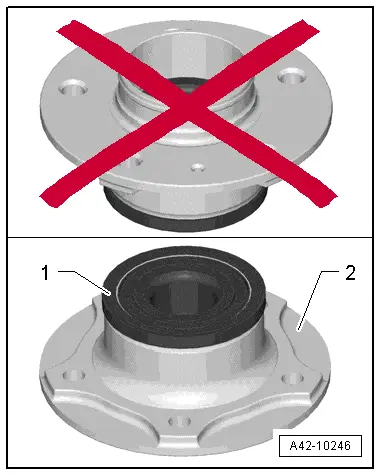

Avoid contaminating with dirt and damaging the seal when setting down/storing.

The wheel bearing -1- must always face up.

- Always set the wheel bearing unit down on the wheel hub -2-.

Installing

Installation is reverse of removal, noting the following:

- Carefully slide wheel hub/wheel bearing unit onto the axle stub.

Make sure that wheel hubs/wheel bearing unit does not tilt!

- Tighten using a new internal multipoint bolt.

Note

Note

- First tighten the bolt to the given tightening specification using the torque wrench.

- Use a rigid wrench to apply additional torque angle.

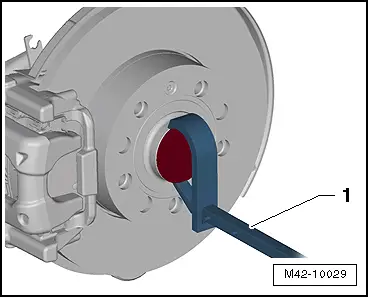

- Install the new dust cap with the Seal Installer - Camshaft Installer Kit - Sleeve -3241/4--1-

Note

Note

- Always replace dust caps.

- Damaged dust caps allow moisture to enter. Therefore, always use the tool shown.

Install in reverse order of removal.

- Install the brake caliper. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Caliper, Removing and Installing.

Wheel Bearing Unit, AWD, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

- Torque Wrench 1410 -VAG1410-

Removing

- Measure dimension from center of wheel to lower edge of wheel housing. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Loosen the outer drive axle threaded connection. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

- Remove the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- Remove the drive axle. Refer to → Chapter "Drive Axle, Removing and Installing".

- Remove the brake caliper with the brake carrier and secure it to the body using wire. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Caliper, Removing and Installing.

Note

Note

Do not let the brake caliper hang on the brake hose - risk of damage.

- Remove the Phillips head bolt for the brake rotor and then remove the brake rotor.

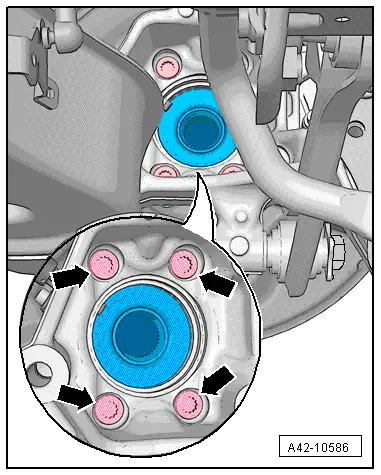

- Remove the bolts -arrows-.

- Remove wheel bearing unit from wheel bearing housing.

Caution

Caution

Avoid contaminating with dirt and damaging the seal when setting down/storing.