Audi Q3: Drive Axle, Removing and Installing

Removing

- Measure dimension from center of wheel to lower edge of wheel housing. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Loosen the drive axle threaded connection. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

- Remove the coil spring. Refer to → Chapter "Spring, Removing and Installing".

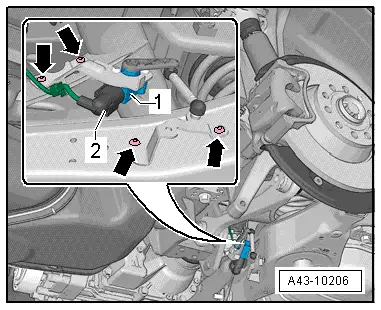

- Remove the bolts -lower arrows- on vehicles with a Level Control System Sensor.

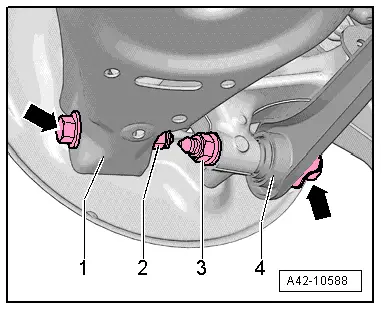

- Remove the bolts -arrows- for the lower control arm -1- and tie rod -4- from the wheel bearing housing.

- Remove the bolt -1- and remove it with the washer -2-.

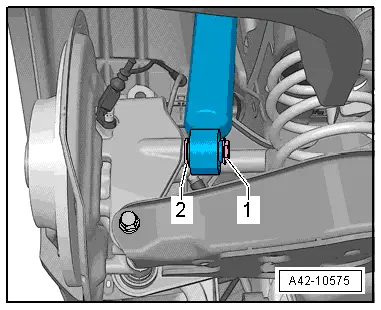

- Loosen the drive axle on the transmission side.

- Pivot the wheel bearing housing outward and remove the drive axle from wheel bearing splines.

- Remove the drive axle.

Installing

Install in reverse order of removal while noting the following:

- Bolting at wheel bearing housing may only occur when the dimension between wheel hub center and lower edge of wheel housing, measured before assembly, is achieved. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Lightly coat the splines on the outer joint with assembly paste before installing the outer joint into the wheel hub. Refer to the Parts Catalog.

- Install the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- On vehicles with electronically controlled damping, perform the function "Adapt the control position" with the Vehicle Diagnosis Tester.

- If the control position was reprogrammed and if the vehicle has lane assist, then it will then be necessary to calibrate the driver assistance systems front camera. Refer to → Chapter "Driver Assistance Systems Front Camera, Calibrating".

- On vehicles with level control system sensor, perform headlamp basic setting. Refer to → Electrical Equipment; Rep. Gr.94; Headlamp, Adjusting.

Tightening Specifications

- Drive axle threaded connection to the rear final drive.