Audi Q3: Drive Axle, Disassembling and Assembling

Drive Axle, Disassembling and Assembling, Drive Axle with 100 mm Inner CV Joint

Special tools and workshop equipment required

- Tripod Joint Tool -T10065-

- Torque Wrench 1331 5-50Nm -VAG1331-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Clamping Pliers -VAG1682A-

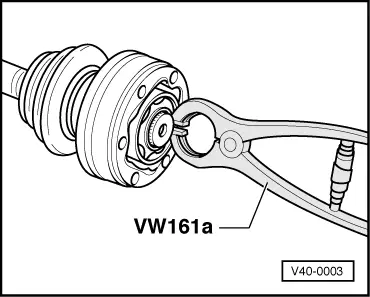

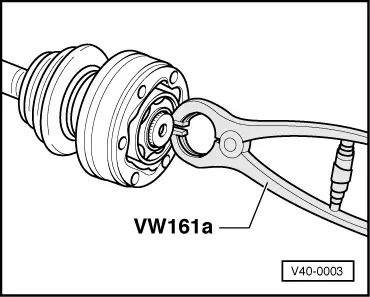

- Circlip Pliers -VW161A-

- Press Plate -VW401-

- Press Plate -VW402-

- Press Piece - Rod -VW408A-

- Press Piece - Rod -VW411-

- Press Piece - 37mm -VW416B-

- Press Piece - Multiple Use -VW447H-

CV Joint, Disassembling

Removing the outer CV joint

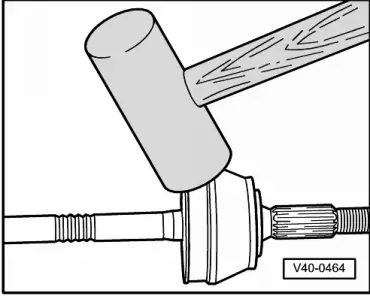

- Remove the CV joint from the drive axle by hitting it with a light alloy hammer.

Circlip, removing and installing

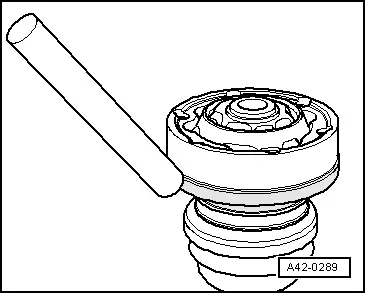

Drive protective joint boot cap under with a brass or copper drift

Removing the inner CV joint

Assembling the CV joint

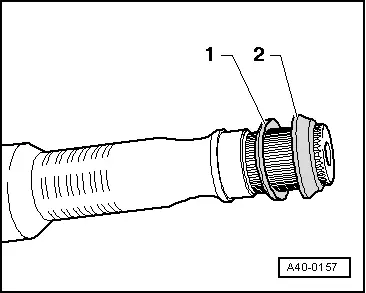

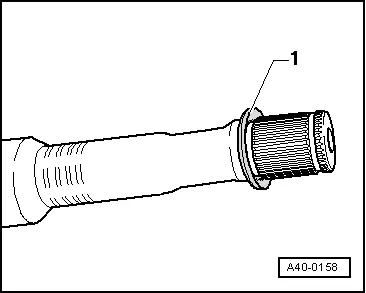

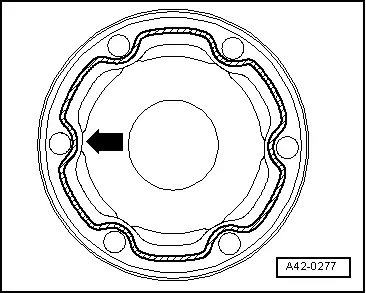

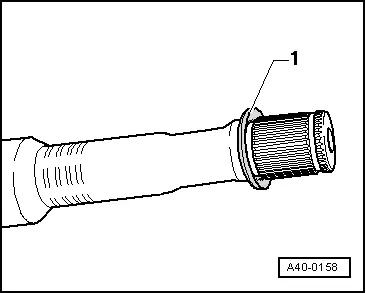

Installed location of spring washer and thrust washer on outer joint

1 - Plate Spring

2 - Thrust Ring

Outer CV Joint with Bolt, Installing

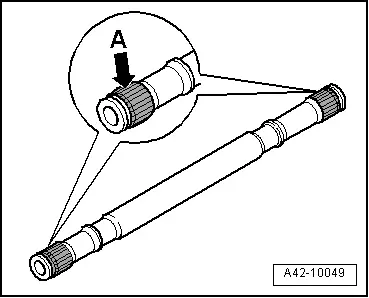

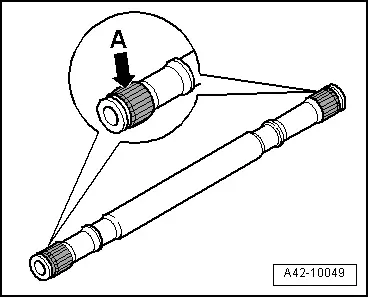

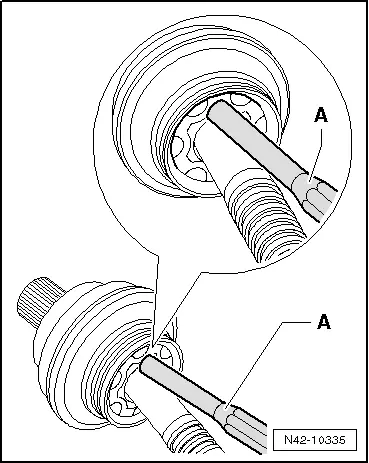

- Before installing joint piece, splines -A- must be lightly coated with grease used in joint.

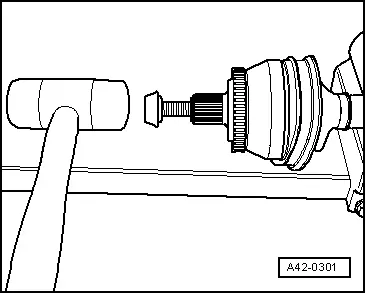

- Install the old bolt in the joint as shown in the illustration.

- Drive joint onto shaft with plastic hammer until circlip engages.

Installed location of the plate spring on inner joint

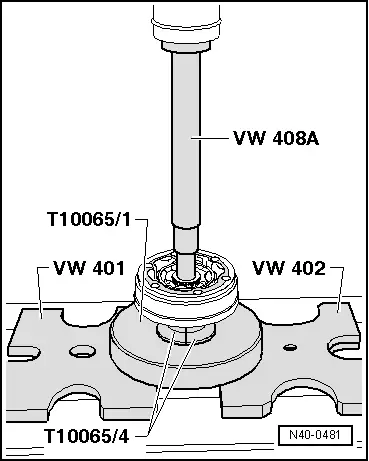

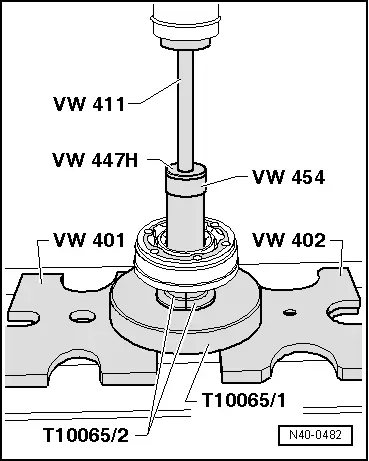

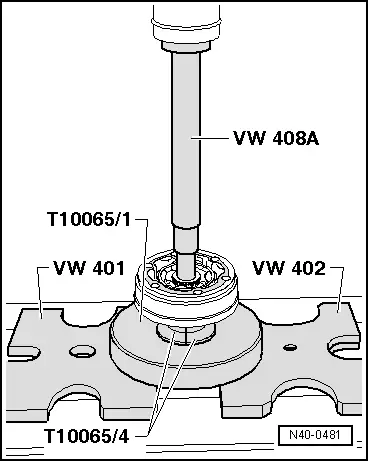

Pressing on Inner CV Joint

- Before installing joint piece, splines -A- must be lightly coated with grease used in joint.

- Install tools as shown in the illustration.

Note

Note

Chamfer on inner diameter of ball hub (splines) must face the contact shoulder on the drive axle.

- Install circlip.

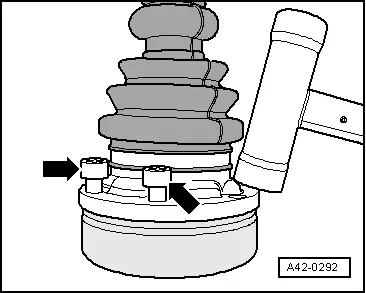

- Apply sealant -hatched surface- to clean surface on inner side of protective joint boot cap. Continuous sealant bead: Diameter 2 to 3 mm skirt area around inner holes -arrow-.

- Use sealant. Refer to the Parts Catalog.

- Slide the CV boot onto drive axle.

The drive axle, CV boot and cap contact surfaces must be free of grease.

Make sure you do not damage the sealant bead.

- Using screws -arrows-, align protective boot and cap with screw holes.

It must be aligned exactly because it cannot be aligned after driving on.

- Drive off the CV boot with cap using plastic hammer.

- Clear away leaking sealing immediately.

Stainless steel clamps for Hytrel protective joint boots, tensioning

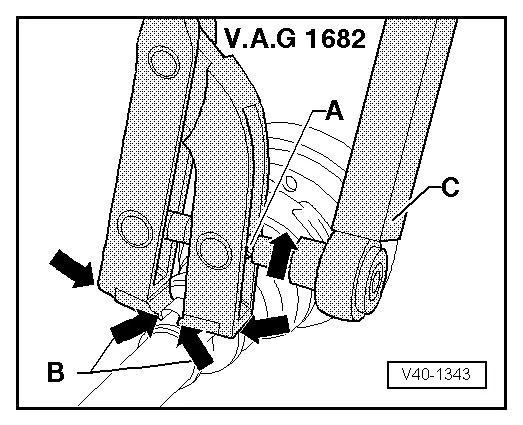

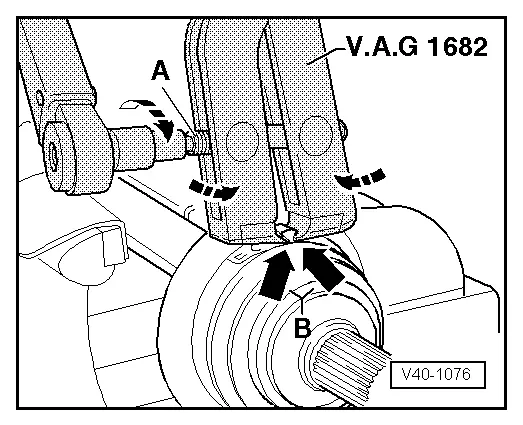

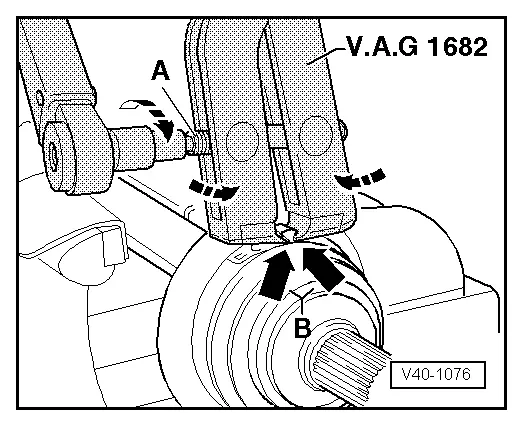

- Position pliers VAG1682 as shown in illustration. When doing this, make sure that edges of clamping pliers are seated in corners -arrows B- of clamp.

- Tighten the hose clamp by turning spindle -A- using a torque wrench (do not tilt clamping pliers).

- Tightening specification: 20 Nm

Note

Note

- Make sure the threads on the spindle on the pliers move easily. Lubricate with MoS2 grease, if necessary.

- If the thread is tight, for example, dirty, the required tensioning force for the hose clamp will not be achieved in spite of correct torque specification settings.

Clamps for rubber protective joint boots, tensioning

Drive Axle, Disassembling and Assembling, Drive Axle with 82 mm Outer CV Joint

Special tools and workshop equipment required

- Tripod Joint Tool -T10065-

- Torque Wrench 1331 5-50Nm -VAG1331-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Clamping Pliers -VAG1682A-

- Circlip Pliers -VW161A-

- Press Plate -VW401-

- Press Plate -VW402-

- Press Piece - Rod -VW408A-

- Press Piece - Rod -VW411-

- Press Piece - 37mm -VW416B-

- Press Piece - Multiple Use -VW447H-

Disassembling

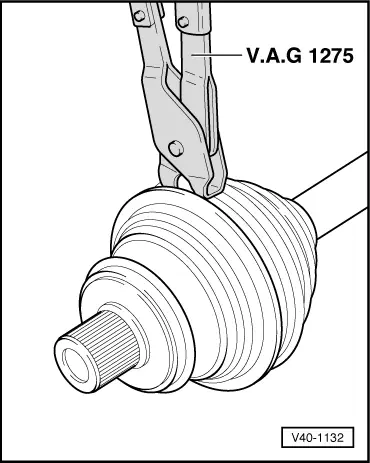

Outer CV joint, pressing off

- Clamp the drive axle with protective jaws in a vise clamp.

- Fold back boot.

- Drive CV joint from drive axle using a drift -A-.

The drift must be installed exactly on the CV joint ball hub.

Driving joint on

- Drive onto shaft with plastic hammer until the circlip engages.

Removing the inner CV joint

- Press off the CV boot from joint using drift.

- Remove the circlip.

- Remove both clamps, and push the CV boot toward outer joint.

Assembling

Dished washer installation position, inner and outer joint

1 - Plate Spring

- Press on joint until stop.

- Install the circlip.

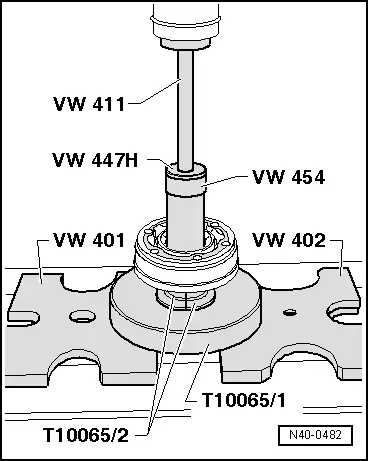

Pressing on inner CV joint

Note

Note

Chamfer on inner diameter of ball hub (splines) must face the contact shoulder on the drive axle.

Tightening clamping sleeve on outer joint

- Attach the Clamping Pliers -VAG1682A- as illustrated. When doing this, make sure that edges of clamping pliers are seated in corners -arrows B- of clamp.

- Tension clamp by turning spindle with a torque wrench (do not tilt clamp tool).

Note

Note

- The hard material of the CV boot (compared to rubber) makes it necessary to use a stainless steel hose clamp. It is only possible to tighten the hose clamp with Clamping Pliers -VAG1682A-.

- Tightening specification: 25 Nm.

- Use torque wrench -C- with adjustment range 5...50 Nm (for example Torque Wrench 1331 5-50Nm -VAG1331-).

- Make sure the threads on the spindle -A- on the pliers move easily. Lubricate with MOS 2 grease, if necessary.

- If the thread is tight, for example, dirty, the required tensioning force for the hose clamp will not be achieved in spite of correct torque specification settings.

Tensioning clamp on small diameter