Audi Q3: Overview - Subframe

Audi Q3 (8U) 2011-2018 Service Manual / Chassis / Suspension, Wheels, Steering / Front Suspension / Overview - Subframe

Caution

Caution

There is a risk of damaging the subframe threaded connection threads on the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

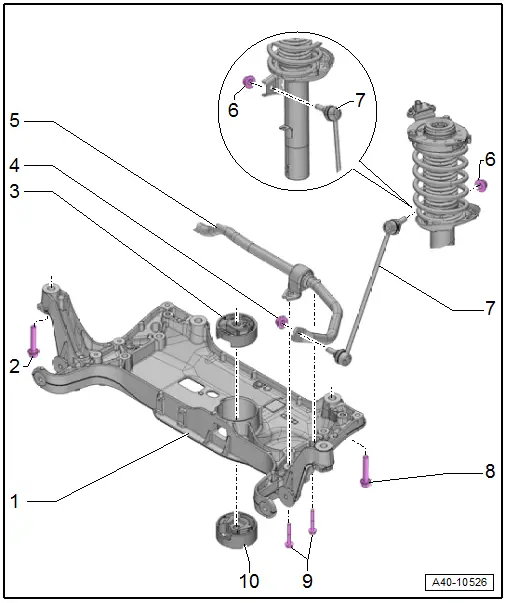

1 - Subframe

- Securing. Refer to → Chapter "Subframe, Securing".

- Lowering. Refer to → Chapter "Subframe, Lowering".

- Removing and installing without steering gear. Refer to → Chapter "Subframe without Steering Gear, Removing and Installing".

- Removing and installing with steering gear. Refer to → Chapter "Subframe with Steering Gear, Removing and Installing".

2 - Bolt

- 70 Nm +180º

- Always replace if removed

3 - Upper Bonded Rubber Bushing for Pendulum Support

- Replacing. Refer to → Chapter "Subframe, Servicing".

4 - Nut

- 65 Nm

- Always replace if removed

- Counterhold at socket head of joint bolt when tightening

5 - Stabilizer Bar

- Removing and installing. Refer to → Chapter "Stabilizer Bar, Removing and Installing".

6 - Nut

- 65 Nm

- Always replace if removed

- Counterhold at socket head of joint bolt when tightening

7 - Coupling Rod

- Removing and installing. Refer to → Chapter "Coupling Rod, Removing and Installing".

8 - Bolt

- 70 Nm +180º

- Always replace if removed

9 - Bolts

- 20 Nm +90º

- Always replace if removed

10 - Lower Bonded Rubber Bushing for Pendulum Support

- Replacing. Refer to → Chapter "Subframe, Servicing".

READ NEXT:

Subframe without Steering Gear, Removing and Installing

Subframe without Steering Gear, Removing and Installing

Special tools and workshop equipment

required

Torque Wrench 1331 5-50Nm -VAG1331-

Torque Wrench 1332 40-200Nm -VAG1332-

Engine and Gearbox Jack -VAS6931-

Removing

Note

Subframe

Subframe, Servicing

Subframe, Servicing

Special tools and workshop equipment

required

Bearing Installer - Wheel Hub/Bearing Kit -T10205-

Torque Wrench 1332 40-200Nm -VAG1332-

Hydraulic Press -VAS6178-

Pneumatic/Hydraulic Foot Pu

Stabilizer Bar, Removing and Installing

Stabilizer Bar, Removing and Installing

Special tools and workshop equipment

required

Locating Pins -T10096-

Torque Wrench 1332 40-200Nm -VAG1332-

Engine and Gearbox Jack -VAS6931-

Puller - Ball Joint -3287A-

Removing

-

SEE MORE:

Overview - Telephone

Overview - Telephone

Overview - Telephone, Cell Phone Pre-Installation, 9ZF

Cell Phone Preparation in Information Electronics Control

Module 1 -J794-, Concert MOST, 9ZF

The Telephone Baseplate -R126- is installed in the center

console. The telephone is operated either by the concert MOST or

by the Cellular Telep

Cockpit

Cockpit

Fig. 1 Cockpit

Door handle

Central locking switch

Air vent with thumbwheel

Lever for:

Turn signals and high beams

High beam assistant

Lane departure warning

Lane guidance

Multifunction steering wheel with:

Horn

Driver's airbag

Operating buttons

Shift paddles

Inst

© 2019-2026 Copyright www.auq3.net