Audi Q3: Drive Axle Threaded Connection, Loosening and Tightening

Special tools and workshop equipment required

- Socket AF 24 mm -T10361A-

- Digital Torque Wrench -VAG1756A-

The wheel bearing must not be under a load while the drive axle threaded connection on the wheel side is loose.

If the bearings are loaded by the vehicle weight the wheel bearing will be damaged. This reduces the service life of the wheel bearings. Observe the following when doing so:

- Procedure for loosening the twelve-point bolt.

Vehicles without a drive axle must not be moved, otherwise the wheel bearing will be damaged. If the vehicle must be moved, be sure to note the following:

- Install an outer joint in place of the drive axle.

- Tighten the outer joint to 200 Nm.

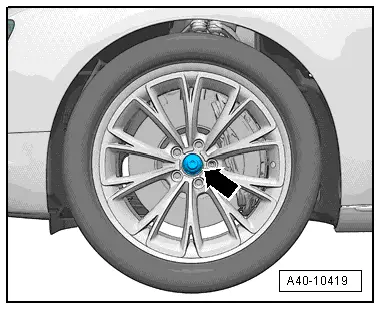

Loosening the twelve-point bolt

- With vehicle still resting on wheels, loosen the twelve-point bolt -arrow- with Socket AF 24 mm -T10361A- maximum 90º, otherwise, the wheel bearing will be damaged.

- Lift the vehicle just enough so that the wheels are hanging free.

- Apply the brakes (a second technician required).

- Remove the twelve-point bolt -arrow-.

Note

Note

Before installing, clean the threads in the CV joint with a tap.

Twelve-point bolt, fastening

- Replace the twelve-point bolt.

Note

Note

Wheels must not yet touch the ground to tighten the drive axle, wheel bearing may otherwise be damaged.

- Apply the brakes (a second technician required).

- Tighten the twelve-point bolt to 200 Nm.

- Lower the vehicle onto the wheels.

- Turn the twelve-point bolt an additional 180º.

Drive Axle Heat Shield, Removing and Installing

Removing

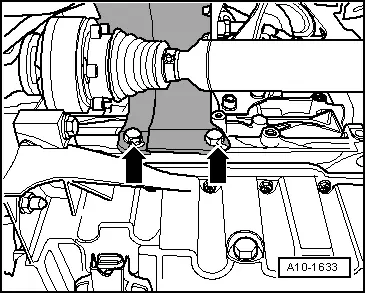

FWD Vehicles

- Remove the nuts -arrows- and then remove the heat shield.

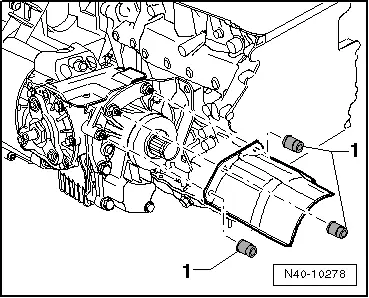

AWD Vehicles Version 1:

- Remove the nuts -1- and then remove the heat shield.

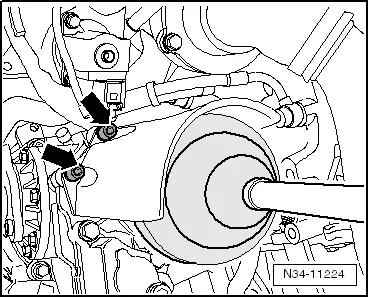

AWD Vehicles Version 2:

- Remove the nuts -arrows- and then remove the heat shield.

Installing

Install in reverse order of removal.