Audi Q3: Subframe, Securing

Special tools and workshop equipment required

- Locating Pins -T10096-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Engine and Gearbox Jack -VAS6931-

Procedure

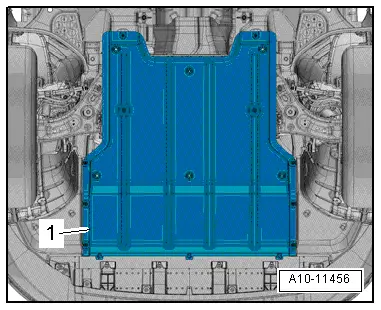

- Remove the noise insulation -1-. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

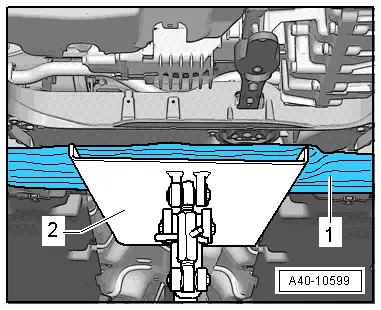

- Position the Engine and Gearbox Jack -VAS6931--2- under the subframe.

- Place, for example, a block of wood -1- between the Engine and Gearbox Jack -VAS6931- and the subframe.

- Clean the locking pin threads if necessary.

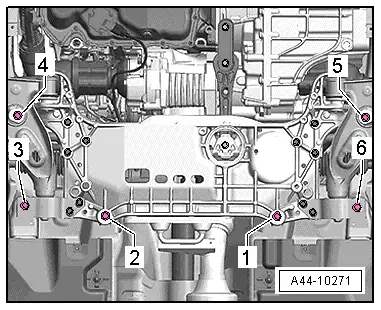

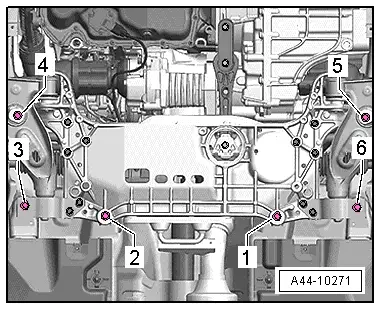

To secure the subframe, the Locating Pins -T10096- must be installed at the positions -3 through 6- one after the other.

- The items -4- and -5- must be secured first.

Note

Note

The locating pins may only be tightened to a maximum of 20 Nm, since otherwise the locating pin threads will be damaged.

Subframe, Securing

Caution

Caution

There is a risk of damaging the subframe threaded connection threads on the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

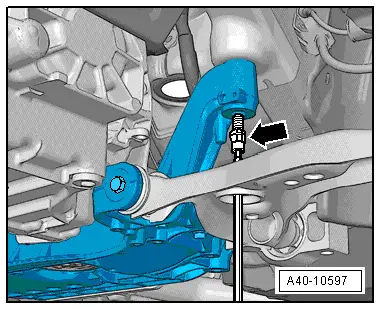

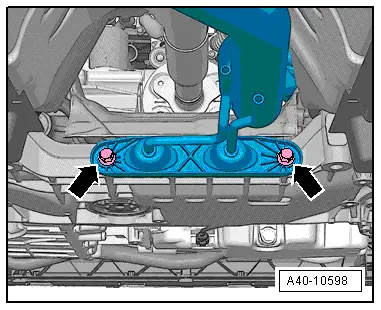

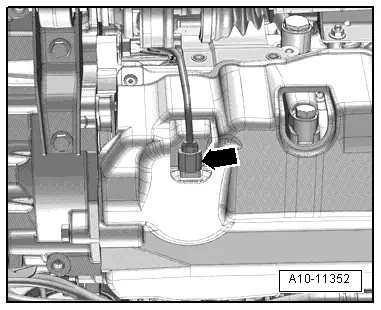

- Replace the bolt one after another on both sides of the vehicle with the Locating Pins -T10096--arrows- and tighten to 20 Nm.

Securing mounting bracket

Caution

Caution

There is a risk of damaging the subframe threaded connection threads on the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

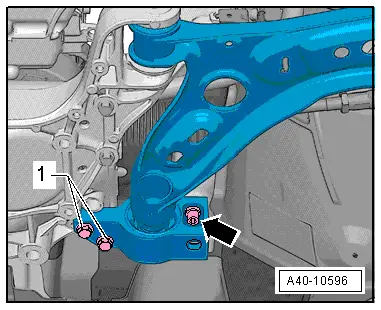

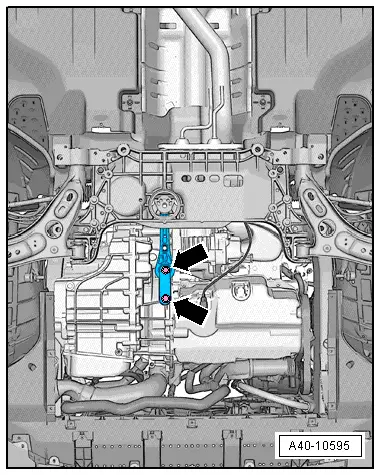

- Replace the bolt one after another on both sides of the vehicle with the Locating Pins -T10096--arrows- and tighten to 20 Nm.

- Securing the subframe is completed when all above mentioned bolts are replaced with Locating Pins -T10096- one after the other.

- Position of front axle is now secured.

Remove the Locating Pins -T10096-.

The removal is reverse of installation, noting the following:

- Always only remove one locating pin and replace it with a new bolt.

After installation, position of steering wheel must be checked with a road test.

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

Subframe, Lowering

Special tools and workshop equipment required

- Locating Pins -T10096-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Engine and Gearbox Jack -VAS6931-

Removing

- Turn the steering wheel to the straight-ahead position and remove the ignition key so that the steering wheel lock engages.

Vehicles with "Keyless Access Authorization System"

- Switch the ignition off and open the driver door so the steering wheel lock locks.

Continuation for All Vehicles

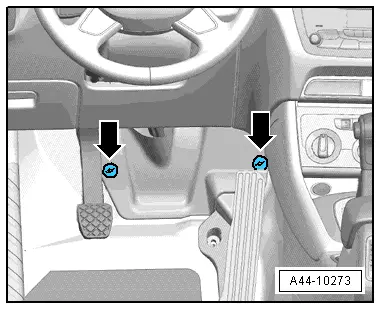

- Remove the footwell trim panel by removing the nuts -arrows-.

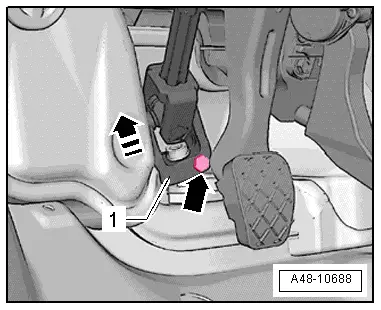

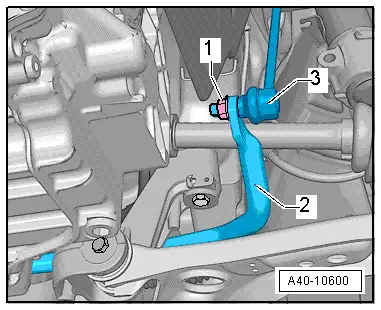

- Remove the bolt -arrow- from the universal joint -1-. Then remove the universal joint from the steering gear in direction of -arrow-.

- Secure the subframe. Refer to → Chapter "Subframe, Securing".

- Remove the bolts -arrows-.

- Remove the bolts -arrows- and then remove the pendulum support from the transmission.

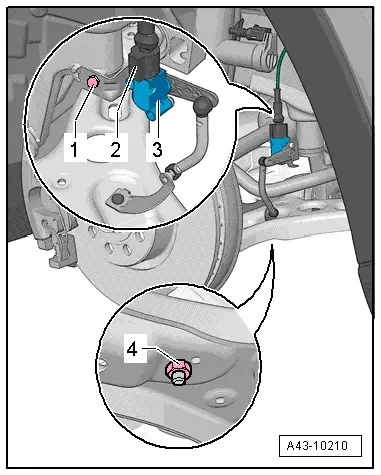

- Remove the left and right nut -1- from the coupling rod -3-.

- Remove the coupling rod -3- from the stabilizer bar -2- on the left and right sides.

- If installed, disconnect the connector -2- from the Left Front Level Control System Sensor -G78- or Right Front Level Control Sensor -G289-.

- Remove the nut -4- and free up the coupling rod from the Left Front Level Control System Sensor -G78- or Right Front Level Control Sensor -G289-.

Vehicles with 4-cylinder Engine

- Disconnect the connector for the Oil Level Thermal Sensor -G266--arrow- and free up the wire.

Continuation for all vehicles

- Remove the remaining bolts -1- and -2- and lower the subframe maximum 10 cm.

Note

Note

Be careful not to overstretch the wire for the steering and the Oil Level Thermal Sensor -G266-.

Installing

Install in reverse order of removal while noting the following:

- Remove the Locating Pins -T10096-.

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

- On vehicles with electronically controlled damping, perform the function "Adapt the control position" with the Vehicle Diagnostic Tester.

- If the control position was reprogrammed and if the vehicle has lane assist, then it will then be necessary to calibrate the driver assistance systems front camera. Refer to → Chapter "Driver Assistance Systems Front Camera, Calibrating".

- On vehicles with level control system sensor, perform headlamp basic setting. Refer to → Electrical Equipment; Rep. Gr.94; Headlamp, Adjusting.

Tightening Specifications

- Pendulum support.

- Exhaust system bracket.