Audi Q3: Subframe, Servicing

Tools and Preliminary Work

Special tools and workshop equipment required

- Hydraulic Press -VAS6178-

- with Bearing Installer - Wheel Hub/Bearing Kit - Pressure Head -T10205/13- from the Bearing Installer - Wheel Hub/Bearing Kit -T10205A-

- Pneumatic/Hydraulic Foot Pump -VAS6179-

- Engine and Gearbox Jack -VAS6931-

- Tensioning Strap -T10038-

- through MY 2012 Locating Pins -T10096-

- from MY 2013 Assembly Tool, Sub-frame Alignment -T10486A-

- Subframe Bushing Assembly Tool Kit -T10356-

Subframe bonded rubber bushing, replacing, only for AWD vehicles

Procedure

- Remove the coil springs. Refer to → Chapter "Spring, Removing and Installing".

- Remove the stabilizer bar. Refer to → Chapter "Stabilizer Bar, Removing and Installing".

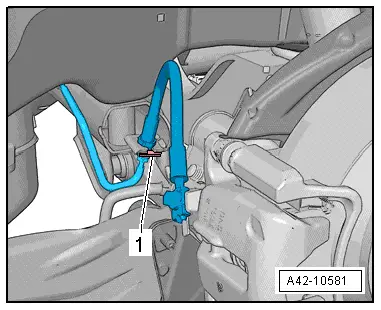

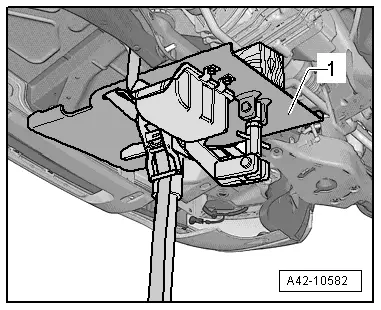

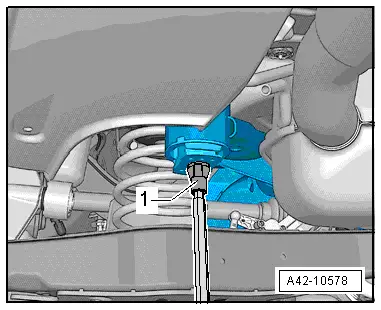

- Remove the clip -1-.

- Free up the brake line.

Note

Note

Do not disconnect the brake line.

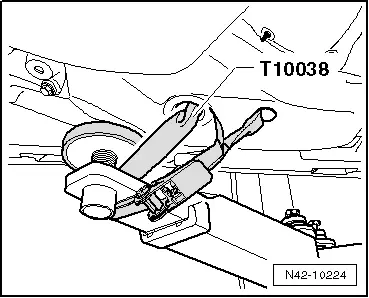

- Now secure vehicle on both sides to lifting arms on hoist with Tensioning Strap -T10038-.

WARNING

WARNING

The vehicle could slide off the hoist if it is not secured.

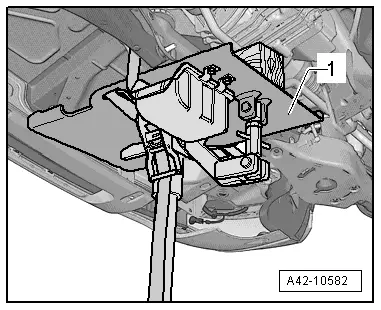

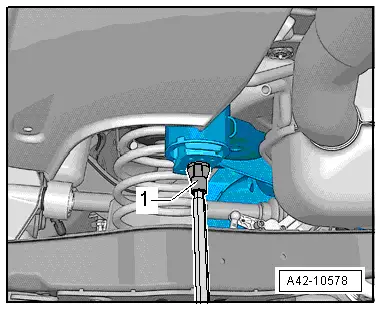

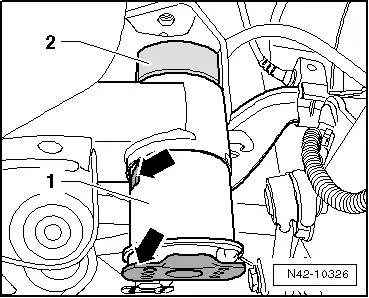

- Move the Engine and Gearbox Jack -VAS6931--1- under the subframe and secure it using the tensioning strap.

Caution

Caution

There is a risk of damaging the subframe threaded connection threads on the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

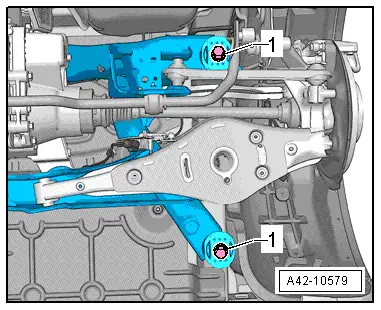

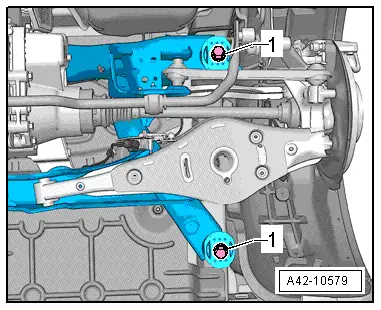

- Remove the front hex bolt -1- from both sides.

Note

Note

Only the left side of the vehicle is shown in the illustration.

To secure the subframe, the Locating Pins -T10096- (through MY 2012) must be installed at positions -1- on both sides of the vehicle one after the other. Use Assembly Tool, Sub-frame Alignment -T10486A- from MY 2013.

- Secure the subframe position using the locating pins -1-.

Note

Note

The locating pins may only be tightened to a maximum of 20 Nm, since otherwise the locating pin threads will be damaged.

- Replace subframe bolts one after the other on both sides using the locating pins and tighten the locating pins to 20 Nm.

The subframe position is now secured.

- Lower the subframe 10 cm using Engine and Gearbox Jack -VAS6931-.

- Mark the installation position of bonded rubber bushing to subframe, for example, with a felt-tip pen.

Front Bonded Rubber Bushing, Servicing

Front bonded rubber bushing, removing

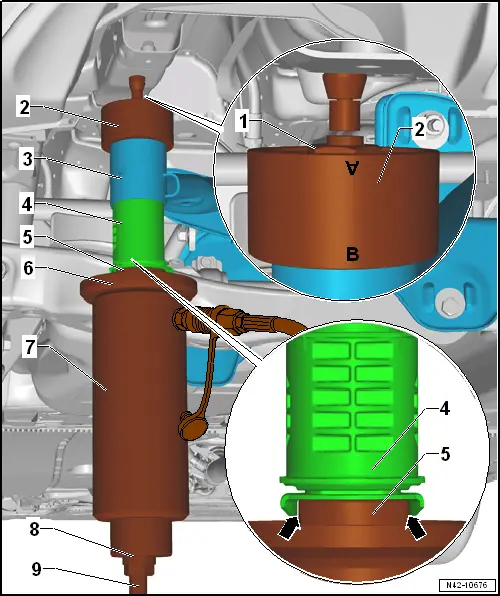

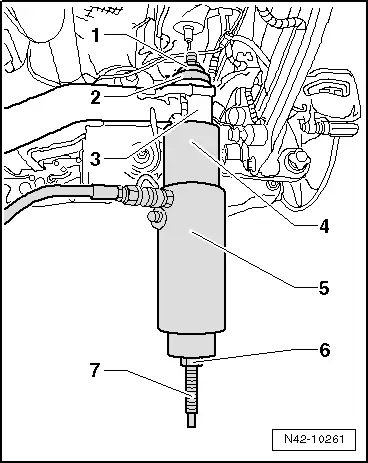

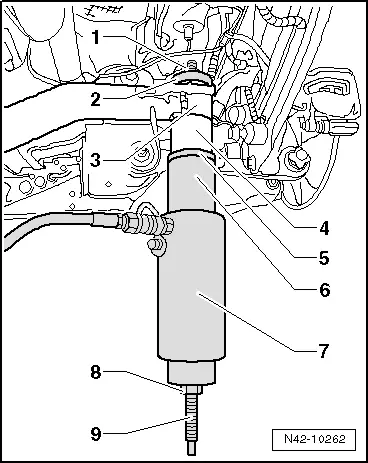

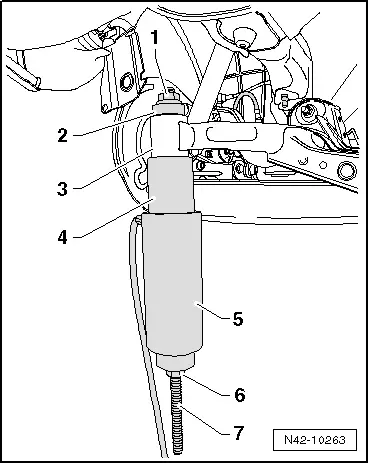

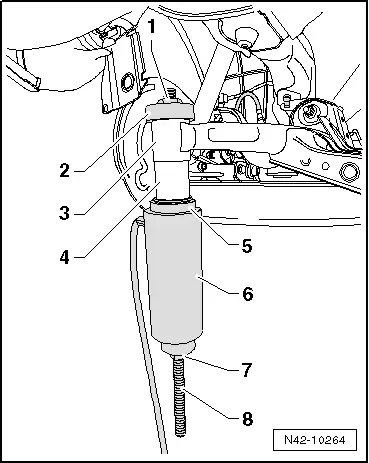

- Install special tools as depicted in the illustration.

1 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

2 - Subframe Bushing Assembly Tool Kit-Press Piece -T10356/1-

3 - Subframe

4 - Subframe Bushing Assembly Tool Kit-Tube -T10356/2-

5 - Hydraulic Press -VAS6178- with Bearing Installer - Wheel Hub/Bearing Kit- Adapter 13 -T10205/13-

6 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

7 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Spindle -T10263/4-

- Pretension special tools.

- Pull out bonded rubber bushing by operating pump.

Note

Note

The bearing outer race is sheared off when the bonded rubber bushing is removed. There is a loud crack when this happens.

- After removing the rubber bonded bushing, it must be removed from the Subframe Bushing Assembly Tool Kit - Tube -T10356/2-.

Installing the front bonded rubber bushing

Install in reverse order of removal. Note the following:

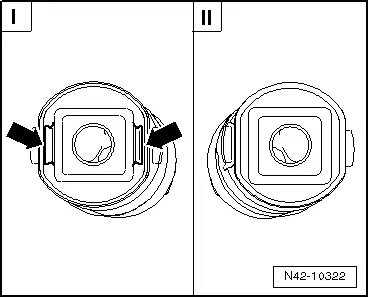

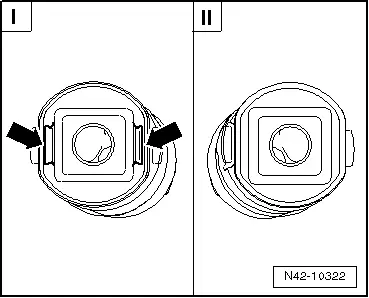

Distinguishing characteristic, rubber bonded bushing

I - Front bonded rubber bushing

II - Rear Bonded Rubber Bushing

The front bonded rubber bushings have two openings -arrows- on the top and have slightly different installation heights. Refer to the Parts Catalog.

Bonded rubber bushing must be installed in the correct direction, note marking on subframe.

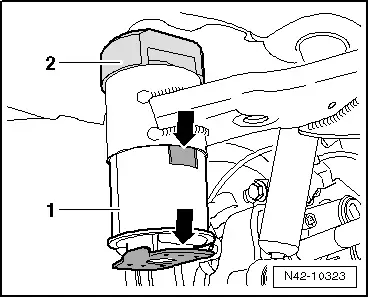

- Install the rubber bonded bushing -1- into the subframe, so that the tab and the plate -arrows- face perpendicular to direction of travel.

- Insert special tools with bonded rubber bushing into subframe as illustrated.

through MY 2013: Refer to Parts Catalog

1 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

2 - Subframe Bushing Assembly Tool Kit - Guide Piece -T10356/3- with side A toward subframe

3 - Subframe

4 - Bonded Rubber Bushing

5 - Subframe Bushing Assembly Tool Kit - Press Piece -T10356/4- with side A toward bonded rubber bushing

6 - Subframe Bushing Assembly Tool Kit-Tube -T10356/2-

7 - Hydraulic Press -VAS6178- with Bearing Installer - Wheel Hub/Bearing Kit- Adapter 13 -T10205/13-

8 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

9 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Spindle -T10263/4-

From MY 2013: Refer to → Electronic Parts Catalog (ETKA)

1 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

2 - Assembly Tool - Bushing -T10356/7- with side A toward subframe

3 - Subframe

4 - Bonded Rubber Bushing

5 - Assembly Tool - Bushing -T10356/8- with side A toward bonded rubber bushing

6 - Subframe Bushing Assembly Tool Kit-Tube -T10356/2-

7 - Hydraulic Press -VAS6178- with Bearing Installer - Wheel Hub/Bearing Kit- Adapter 13 -T10205/13-

8 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

9 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Spindle -T10263/4-

- Pretension special tool with bonded rubber bushing.

- Carefully insert bonded rubber bushing by operating pump until collar lies on subframe "without a gap".

Rear Bonded Rubber Bushing, Servicing

Pulling out rear bonded rubber bushing

- Move the Engine and Gearbox Jack -VAS6931--1- under the subframe and secure it using the tensioning strap.

Caution

Caution

There is a risk of damaging the subframe threaded connection threads on the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

- Remove the rear hex bolt -1- from both sides.

Note

Note

Only the left side of the vehicle is shown in the illustration.

To secure the subframe, the Locating Pins -T10096- (through MY 2012) must be installed at positions -1- on both sides of the vehicle one after the other. Use Assembly Tool, Subframe Alignment -T10486A- from MY 2013.

- Secure the subframe position using the locating pins.

Note

Note

The locating pins may only be tightened to a maximum of 20 Nm, since otherwise the locating pin threads will be damaged.

- Replace subframe bolts one after the other on both sides using the locating pins and tighten the locating pins to 20 Nm.

The subframe position is now secured.

- Lower the subframe 10 cm using Engine and Gearbox Jack -VAS6931-.

- Mark the installation position of bonded rubber bushing to subframe, for example, with a felt-tip pen.

- Install special tools as depicted in the illustration.

1 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

2 - Subframe Bushing Assembly Tool Kit - Thrust Piece-T10356/5-

3 - Subframe

4 - Subframe Bushing Assembly Tool Kit - Tube -T10356/6-

5 - Hydraulic Press -VAS6178- with Bearing Installer - Wheel Hub/Bearing Kit- Adapter 13 -T10205/13-

6 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

7 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Spindle -T10263/4-

- Pretension special tools.

- Pull out bonded rubber bushing by operating pump.

Note

Note

The bearing outer race is sheared off when the bonded rubber bushing is removed. There is a loud crack when this happens.

- After removing the rubber bonded bushing, it must be removed from the Subframe Bushing Assembly Tool Kit - Tube -T10356/2-.

Pulling in rear bonded rubber bushing

Install in reverse order of removal. Note the following:

Distinguishing characteristic, rubber bonded bushing

I - Front bonded rubber bushing

II - Rear Bonded Rubber Bushing

The front bonded rubber bushings have two openings -arrows- on the top and have slightly different installation heights. Refer to the Parts Catalog.

Bonded rubber bushing must be installed in the correct direction, note marking on subframe.

through MY 2013: Refer to Parts Catalog

- Install the rubber bonded bushing -1- into the subframe, so that the tab and the plate -arrows- face perpendicular to direction of travel.

- Mount the Hydraulic Press - Rear Subframe Bushing Tool Kit - Pressure Piece -T10263/3--2- so that the flat side faces perpendicular to direction of travel.

- Insert special tools with bonded rubber bushing into subframe as illustrated.

1 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

2 - Subframe Bushing Assembly Tool Kit - Guide Piece -T10356/3- with side B toward subframe

3 - Subframe

4 - Bonded Rubber Bushing

5 - Subframe Bushing Assembly Tool Kit - Press Piece -T10356/4- with side B toward bonded rubber bushing

6 - Hydraulic Press -VAS6178- with Bearing Installer - Wheel Hub/Bearing Kit- Adapter 13 -T10205/13-

7 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

8 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Spindle -T10263/4-

From MY 2013: Refer to Parts Catalog

- Insert special tools with bonded rubber bushing into subframe as illustrated.

1 - Hydraulic Press - Rear Subframe Bushing Tool Kit - Nut -T10263/5-

2 - Assembly Tool - Bushing -T10356/7- - the marking -B- points to the subframe

3 - Subframe

4 - adjust the bonded rubber bushing to the marks (the marks need to align)

5 - Assembly Tool - Bushing -T10356/8- - the flattened sides need to fit into the cover of the bonded rubber bushing -arrows-.

6 - Bearing Installer - Wheel Hub/Bearing Kit - Gripping Device -T10205/1-

7 - Hydraulic Press -VAS6178- with Bearing Installer - Wheel Hub/Bearing Kit Pressure Head -T10205/13-

8 - Hydraulic Press - Rear Subframe Bushing Tool Kit - Nut -T10263/5-

9 - Hydraulic Press - Rear Subframe Bushing Tool Kit - Threaded Rod -T10263/4-

- Pretension special tool with bonded rubber bushing.

- Carefully insert bonded rubber bushing by operating pump until collar lies on subframe "without a gap".

Install in reverse order of removal.

- Install the coil springs. Refer to → Chapter "Spring, Removing and Installing".

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".