Audi Q3: Overview - Subframe

Audi Q3 (8U) 2011-2018 Service Manual / Chassis / Suspension, Wheels, Steering / Rear Suspension / Overview - Subframe

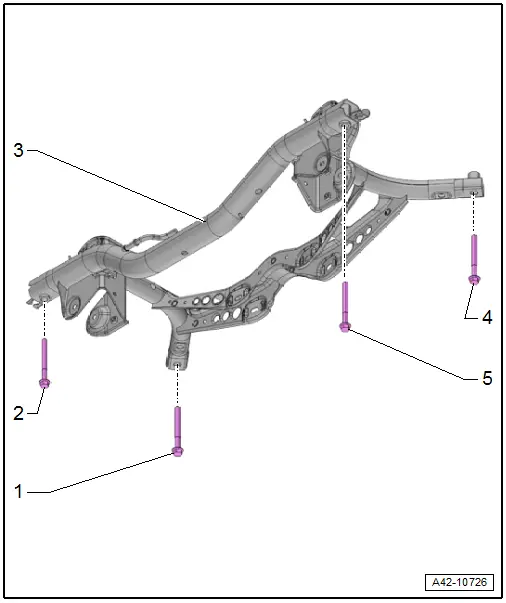

Overview - Subframe, Vehicles with FWD

Caution

Caution

There is a risk of damaging the subframe threaded connection threads on the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

1 - Bolt

- 90 Nm + 90º

- Always replace if removed

2 - Subframe

- Removing and installing. Refer to → Chapter "Subframe, Removing and installing, FWD Vehicles".

3 - Bolt

- 90 Nm + 90º

- Always replace if removed

4 - Bolt

- 90 Nm + 90º

- Always replace if removed

5 - Bolt

- 90 Nm + 90º

- Always replace if removed

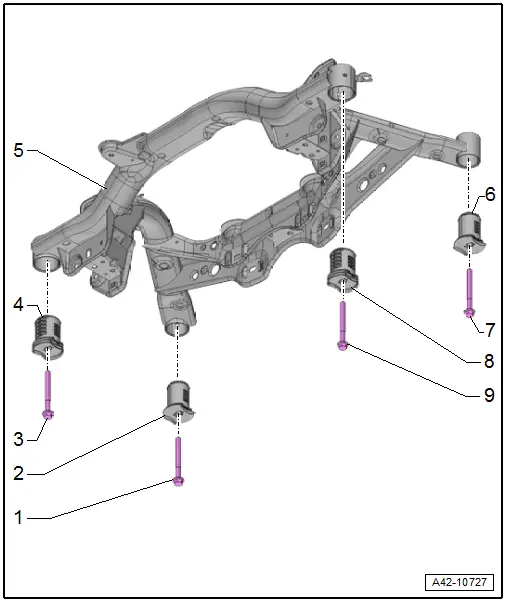

Overview - Subframe, Vehicles with AWD

Caution

Caution

There is a risk of damaging the subframe threaded connection threads on the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

1 - Bolt

- 90 Nm +90º

- Always replace if removed

2 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Subframe, Servicing".

3 - Bolt

- 90 Nm +90º

- Always replace if removed

4 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Subframe, Servicing".

5 - Subframe

- Removing and installing. Refer to → Chapter "Subframe, Removing and Installing, AWD Vehicles".

- 6 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Subframe, Servicing".

7 - Bolt

- 90 Nm +90º

- Always replace if removed

8 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Subframe, Servicing".

9 - Bolt

- 90 Nm +90º

- Always replace if removed

READ NEXT:

Subframe, Removing and Installing

Subframe, Removing and Installing

Subframe, Removing and installing, FWD Vehicles

Special tools and workshop equipment

required

Locating Pins -T10096-

Torque Wrench 1332 40-200Nm -VAG1332-

Engine and Gearbox Jack -VAS6931-

Subframe, Servicing

Subframe, Servicing

Tools and Preliminary Work

Special tools and workshop equipment

required

Hydraulic Press -VAS6178-

with Bearing Installer - Wheel Hub/Bearing Kit - Pressure

Head -T10205/13- from the Bearin

Stabilizer Bar

Stabilizer Bar

Overview - Stabilizer Bar

1 - Subframe

2 - Bolt

25 Nm + 45º

Always replace if removed

Install evenly

3 - Clamp

4 - Bearing

Always replace t

SEE MORE:

Inner Window Shaft Strip, Removing and Installing

Inner Window Shaft Strip, Removing and Installing

Removing

- Remove the front window frame trim panel. Refer to

→ Body Interior; Rep. Gr.70; Front Door Trim; Window Frame Trim

Removing and Installing.

- Remove the window shaft strip -1-

upward -arrows-.

Installing

Install in reverse order of removal. Note the f

Jump starting

Jump starting

Preparation

You should only perform the steps that follow if

you have the necessary tools and technical expertise.

If the engine does not start because the vehicle

battery is drained, you can jump start your vehicle

using another vehicle. Jump start cables are

needed to do this.

Both vehicle batteri

© 2019-2025 Copyright www.auq3.net